Heartfelt revolution

When Peter Wagner talks about the early days you get a sense of the enthusiasm that led the family firm to success and continues to shape it to this day: “My brother and I grew into chair production from an early age; I learned how to upholster at the age of five,” he laughs. In 1950 their grandfather Moritz Wagner set up his small chair factory in Langenneufnach near Augsburg. Conceived for bars and taverns, the wooden chair with specially developed glued plug joints was the first product – and remains a timeless classic today. Sturdy, functional and pared down to the essentials, the “W-1960” fits easily into any setting. An aesthete at heart, Moritz Wagner chose for the typography a Bauhaus font and in so doing established the basic values: clarity, design and quality. Over the years the family never entertained the idea of leaving their idyllic location: “We would never move away or hand over the company to an outsider,” says Peter Wagner. In founding the office chair brand Topstar in 1976 his father Michael, son of Moritz Wagner, displayed a keen sense for the latest trends from his Swabian-Bavarian community: That same year Steve Jobs established Apple and set about realizing the idea of a personal computer. As more people used computers at home the need for office chairs for the home also grew, indeed the demand for Topstar hit the roof. “We worked as a team around the clock and increased production from 1,000 to 10,000 a day,” explains Peter Wagner. Despite this gearing towards products that would appeal to the broad majority, it was clear that the quality must be maintained. “When the customer buys a product from us he expects high quality. We can’t afford to deliver a poor performance,” he says.

The right dose

In the late 1990s brothers Rainer and Peter Wagner decided to develop a premium brand alongside Topstar, a brand based on a scientific approach: Wagner Living. The Dondola joint developed by Stephan Meyer became the core of the concept and continues to serve as the inspiration for all subsequent products to this day. By decoupling the rigid connection to the chair base, the Dondola mechanism of the swivel chair becomes an extension of the spine. “It is all about the right dose, not about having a chair that moves as much as possible,” explains Peter Wagner. This dynamic sitting permits micro movements that reduce strain on the discs in the back and strengthen them, as well as improving concentration. Wagner has already realized four patents with Dondola and conducted extensive research into sitting that confirms the positive impact of this technology on health. “I don’t want to sell customers mass products, but comfortable sitting,” says Peter Wagner. In collaboration with Stefan Diez the company advanced the Dondola seat joint and used it to create the “D1” range of swivel chairs. It was Charles Schumann, legendary barkeeper and the face of the Wagner brand, who originally arranged the contact to the industrial designer, and it quickly developed into a friendship: “Stefan has become like a fourth brother for us, he unites science and imagination in a single person. We couldn’t have been more fortunate,” sums up Peter Wagner.

Now, alongside the advancement of the “D1” collection their close cooperation is being continued with a service for interior designers aimed at enabling room design from a single source. With an international focus and a sustainable concept, the customized items are to be realized with local workshops. The visionary force and originality of the Wagner brand will soon also be visible on the company premises covering some 100,000 square meters: Above the ground floor of what was once the family home there is to be a “Design Lab.” Designed by architecture studio Titus Bernhard, the building will simultaneously serve as a design lab, showroom and workplace. It will feature two insulating glass panels 20 meters long and 3.5 meters high (the largest in the world used in a building), which will open up the building on the long sides as in a display window. It is already possible to inspect the new Wagner projects here, such as a bed with Dondola joints with which the brothers want to provide unique value added in future, for boutique hotels, for instance.

Looking ahead

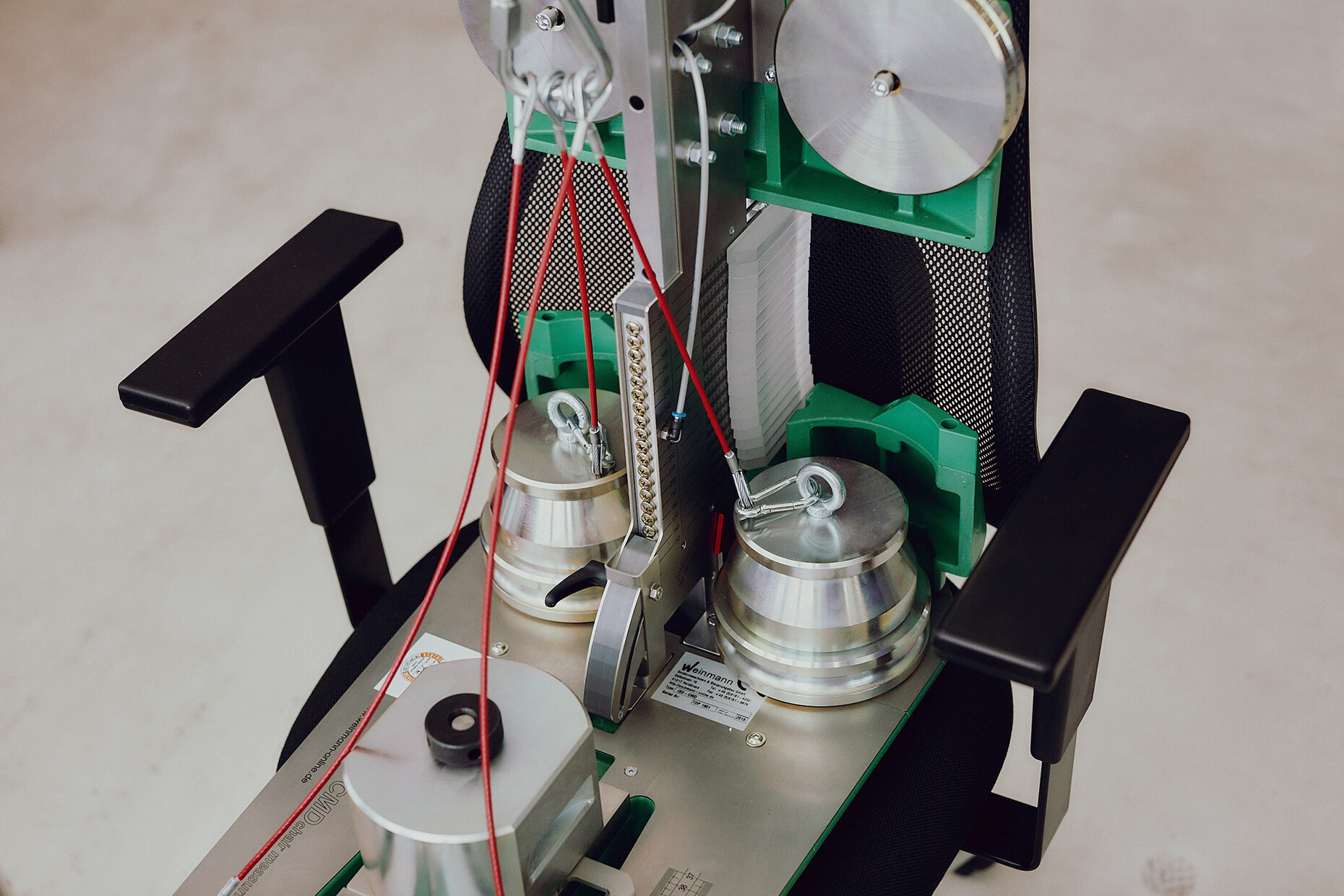

Wagner’s good sense for ground-breaking technology is also visible on a tour of the modern production facilities. Directed by GPS signals, small robotic vehicles flit through the building and supply the various workstations with components. In introducing Industry 4.0 technology for production, Wagner has created the first real-time-controlled production line for high-quality seating furniture in Europe. Thanks to this support, employees save a lot of time every day and the physical strain is reduced while enhancing production. In the development center a few floors higher up, Wagner is doing research on seats for autonomous vehicles like the UCCON W-Mobil, which premiered at the IAA in 2018. Then there are several 3D printers designed to make it easier to cater to special requirements and move chair production in a new direction in the not too distant future. Peter Wagner plans to unveil the findings of this research at Orgatec 2020. “The 3D-printed chair is currently my passion,” he says and grins. Digital manufacturing and optimized processes might be a key element of production, but the company does not want to exclude the analog side completely: “You need to keep a proverbial eye on quality,” argues Peter Wagner.

With a factory planned on the company premises, in the next few years it will be possible to take a look at the craft side of things that defined the company’s early days: “I have been looking forward to reviving my grandfather’s factory for some time now,” says Peter Wagner. His grandfather’s visionary ideas and warm-heartedness have defined the company philosophy from the start. “We want our staff to feel at home here,” he says. And for Wagner, feeling good at work also involves sustainable production: Chemical glues are no longer allowed, electricity is provided by hydropower and a photovoltaic system, while heating is by natural gas. Moreover, the latest clever idea involves the paper waste from packaging. Amounting to around 2,000 tons a year, it is now shredded and used as filling for the packing pads.

Wholly in line with the company slogan “Move your life,” Peter and Rainer Wagner are advancing developments in seating with a keen eye, cutting-edge technologies and high standards of design and quality. “We want sitting to be valued more highly,” says Peter Wagner.