A touch finer

Especially thin, refined edges and beautiful shapes are currently all the rage for washbasins, above all surface-mounted washbasins. This trend cries out for a ceramic material that can be utilized with thinner walls, combining the properties of high-grade sanitary ceramics with extraordinary stability. In fact, the cherished shapes are only possible if such materials are deployed. At Villeroy & Boch, engineers in the ceramic development section spent 2 ½ years tinkering, researching and testing things until, back in 2015, they proudly presented “TitanCeram”, the material of tomorrow. In order to make it, natural raw materials such as feldspar, quartz, clay and titanium dioxide are processed to form a homogeneous ceramic mass. And to guarantee that the basic material possesses the best possible properties, the components are milled, mixed and filtered on the Villeroy & Boch premises. The innovative "TitanCeram" material enables objects to be made with truly refined shapes, extremely thin walls and perfectly molded edges.

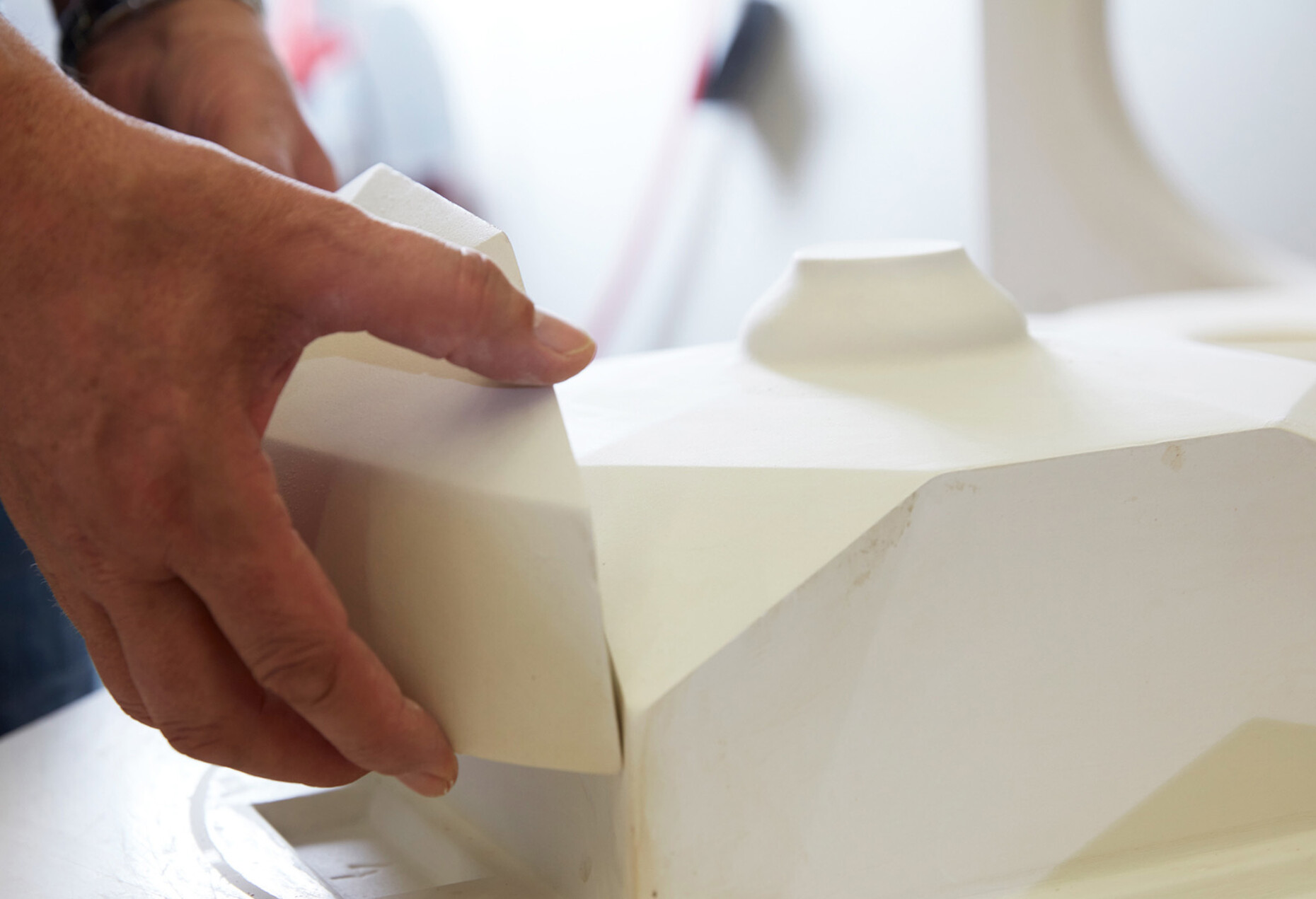

Designers really appreciate "TitanCeram"’s special material properties, as it lays the foundations for them not only to be able to design graceful silhouettes and highly-complex geometries, but also actually make them. For example, Kai Steffan relies on the novel material (which produces just a low shrinkage during the firing process and thus ensures prime dimensional tolerance of the products) for his “Octagon” pedestal washstand, which boasts a fitting rim only 5 millimeter thick. Moreover, there are facets inside the basin reminiscent of a polished diamond: Here Steffan transposes the shape of an octagon into the ceramics in a striking way and thus gives rise to a completely new type of washstand design. The geometrical figure of the "Octagon" creates a surprising effect inside the basin that you hardly expect to encounter on first sight.

In order to be able to make such thin ceramic pieces the “Octagon” basin is cast in many small parts, unlike the usual practice of two-section basins. Without "TitanCeram" it would simply not have been possible to realize the design – it is cast by experienced staff members by hand rather than mass produced. “Octagon” is very special in this regard, as many mass-production processes today are fully automated, bar deburring the casts and the final quality controls. “Octagon” stands for true precision and small unit numbers. And a special glaze gives the column a pleasant touch. That such thin edges can be completely and evenly coated is the result of the precise viscosity of the glaze. And thanks to the specially developed glaze for the "Octagon", the ceramics also boasts a high-grade and particularly resistant surface texture that protects it ideally against external factors. An impact test was used specially for Steffan’s design to measure the ceramic’s resilience. Thanks to "TitanCeram" the thin edges are highly durable.

Not that only the “Octagon” basin is made of "TitanCeram". Other designs in the company’s premium collection, such as “Memento 2.0”, “Antheus”, and “Finion” rely on the properties of the innovative material, as do the surface-mounted washbasins in the “Artis” series – the four different variants (circular, oval, rectangular and square) feature deep, functional basins that are visually appealing and exceptionally comfortable to use. For “Artis”, designer Gesa Hansen purpse-developed a color concept inspired by the changing colors of the four seasons in Paris. There are three nuanced tones available for each of the color worlds of green, yellow, rose and blue; and the basins are available in three elegant black and gray tones. In particular, the bicolor version demonstrates the impressive range of modern color designs: The outside edge entails a white wraparound edge that is merely one millimeter thick. Unadulterated precision.