Featured

New Standards

Anna Moldenhauer: Are you saying that the “DUO” technology is setting new standards in the carpet industry?

Heiko Kühnen: Oh, we are definitely setting a new benchmark because we are aiming to achieve one hundred percent circular products with this process. In other words, we are reducing the materials used to an absolute minimum. We are following completely new principles in recyclable design. This means that even after the end of its lifecycle we can easily separate the materials we combine to make a carpet.

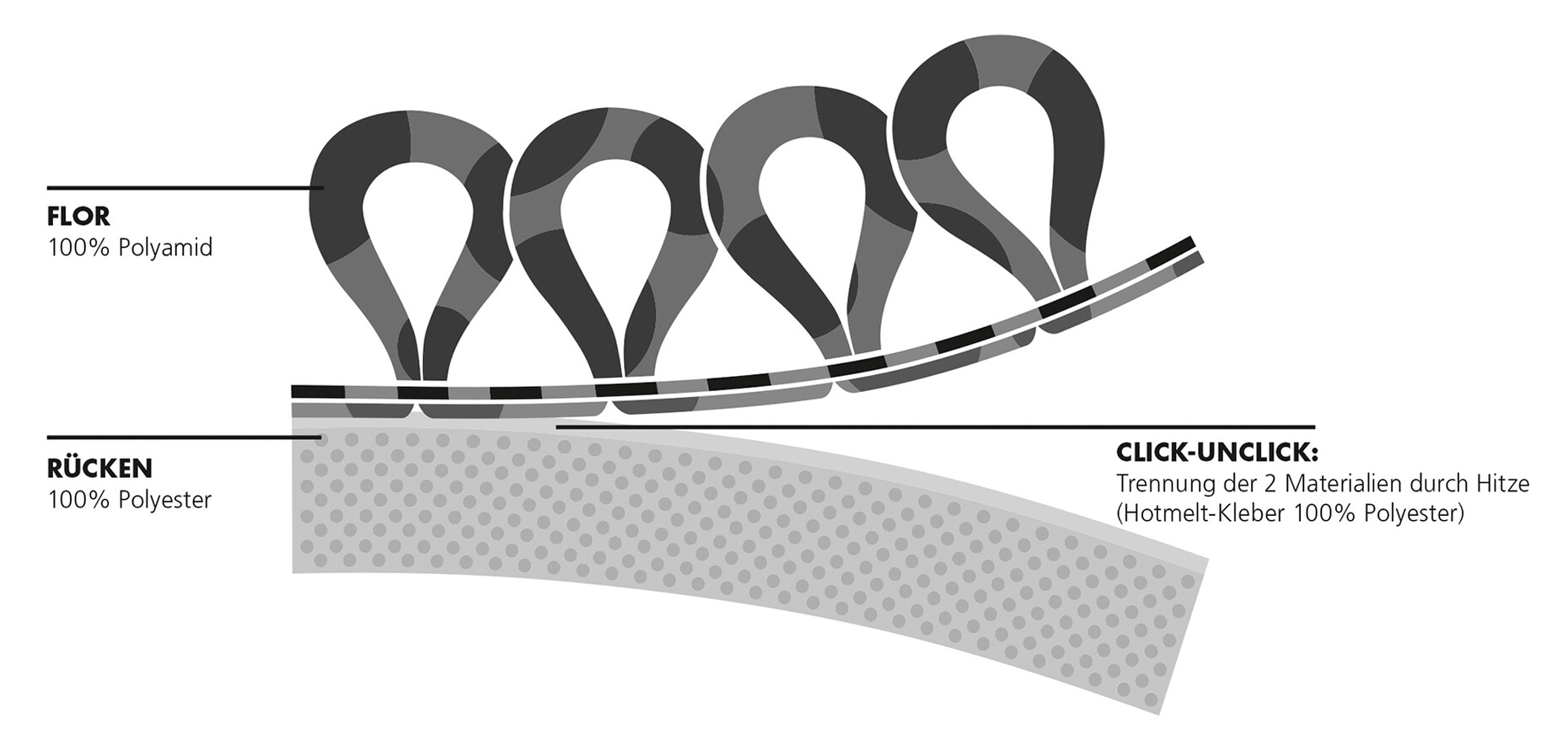

The “DUO” carpet product family has two basic materials: the pile is made of polyamide while the backing is made of polyester. The hotmelt adhesive is also made of polyester. How complex did the process need to be to achieve this?

Heiko Kühnen: As the issue of resources is fundamental for us, we at Object Carpet have been working on a wide range of technologies since 2018. Before embarking on a completely new production technology, we already worked very intensively in a project group on the requirements for the future. What materials will we use in future? What must our carpet be like to be fit for the future regarding the requirements for product recyclability? We have been in the implementation phase for three years.

To what extent could you draw on the insights you gained developing the circular object carpet “NEOO” for the production of “DUO”?

Heiko Kühnen: We use a completely new coating technology, the so-called NIAGA-technique. This means we avoid using classic polymer dispersion as a coating material for the back which would involve many different substances. So, the top layer, in other words the one you walk on during the usage phase is conceived according to different criteria, as we pin and then fuse only two materials together in order to ensure a highly durable bonding: the base material and the poly layer. This also eliminates the need to apply aqueous dispersions and then dry them. The polyester adhesive serves as an intermediate layer for bonding the top layer to the carpet backing, i.e., the secondary backing system. And as we use special process parameters the two layers can also be separated from one another again. We have already implemented this process with the “NEOO” carpet, which is made entirely of polyester. Polyamides play a major role in the contract sector and it was clear to us that we could not reduce our range of applications to a monomaterial. Which is why we then set about developing “DUO”. Here we combine a polyamide top layer and a second layer of polyester enabling us to easily separate these two materials from each other at a later stage and feed them into the appropriate recycling system.

Can you explain how the “Click / Unclick” technology works?

Heiko Kühnen: We apply the hotmelt adhesive in the middle of the pre-bound outer fabric and the secondary backing system. As the polyester adhesive has a relatively low melting point it is ideal for bonding the components while using less energy. We achieve excellent bonding results with it. We are also able to dissolve this layer again afterwards by exposing it to temperatures above 100 degrees centigrade. And as it is a two-way process the technology we use to bond the two layers can also be used later to separate them.

“DUO” is extremely robust and consequently has a long lifecycle. How do you achieve that?

Heiko Kühnen: We have to stick to the structure for a solid pile, but the way we assemble it changes. We have collaborated with a number of system partners to develop the modified materials we use for this. It is important to know the properties of the polymers when fusing them together.

You plan to switch your entire range to the DUO technology by 2026; that involves over 1000 products. What do you need to consider?

Heiko Kühnen: The most important criterion is to really rethink the products in many areas and not to start product development with the conventional approach. There are a lot of details that need to be considered in design development to ensure that this technology works. The challenge we are currently facing is to adapt a thousand positions accordingly. Circularity is our clearly-defined object. It is not a matter of having to reinvent everything, but it does involve adjusting the parameters and replacing various materials.

Your products “Madra”, “Silky Seal” and “Smoozy” can already be produced in 85 colors using the “DUO” technology. Which ones are next in line?

Heiko Kühnen: “Greencard” is one of the next collections we plan to realize with the “DUO” technology and others will follow on from there.

How does Object Carpet Return work?

Heiko Kühnen: We have tested recycling methods for the monomaterials with various institutions and industrial partners and are doing the same with the “DUO” products. One important system partner is AQUAFIL, which produces so-called Econyl® yarns. We have conducted process trials and recycling tests with them to prove what we have realized in theory and ultimately in practice can actually be separated and fed into the recycling loop. Initially, that was one of our main tasks. Currently we are in the process of conceiving the whole thing in such a manner that we will also be able to demonstrate in future how these materials can be recycled. It’s a challenging task because we have to bring many parties together so as to create an infrastructure for the material cycle. We have solved the purely technical side of recycling, now the decisive thing is cooperation with the waste management industry.

Do you feel that the use of take-back systems has already become established in the minds of customers and company management?

Heiko Kühnen: Yes and no, but there is momentum and the demand for circular goods is increasing. There is more and more movement in the industry and we addressed the issue of sustainability early on. Essentially, we should all have understood by now that something has to change. Legislation is also setting new requirements that will change the industry. Many architectural firms have already defined their own standards and created their own sets of questions to map them out.

Are there an other projects you can tell us about?

Heiko Kühnen: We are setting up a tech lab for the new coating technology that is a world first right now. It’s a decisive step for us because it provides us with a means of trying out a number of possibilities – like simulating a wide variety of development steps on a small scale before we scale things up.

You have been working at Object Carpet for a good 30 years. What do you find so attractive about the industry?

Heiko Kühnen: What I find so attractive at Object Carpet is the agility, activity, and innovative spirit. That’s not a given everywhere and has always been very challenging and interesting. What particularly drives me at the moment is being able to help change the awareness for the environment in the industry and society. Opportunities have to be created for this change to take place. Object Carpet is visionary in this respect and that motivates me to remain engaged with passion.