SUSTAINABILITY

Smart lightweight

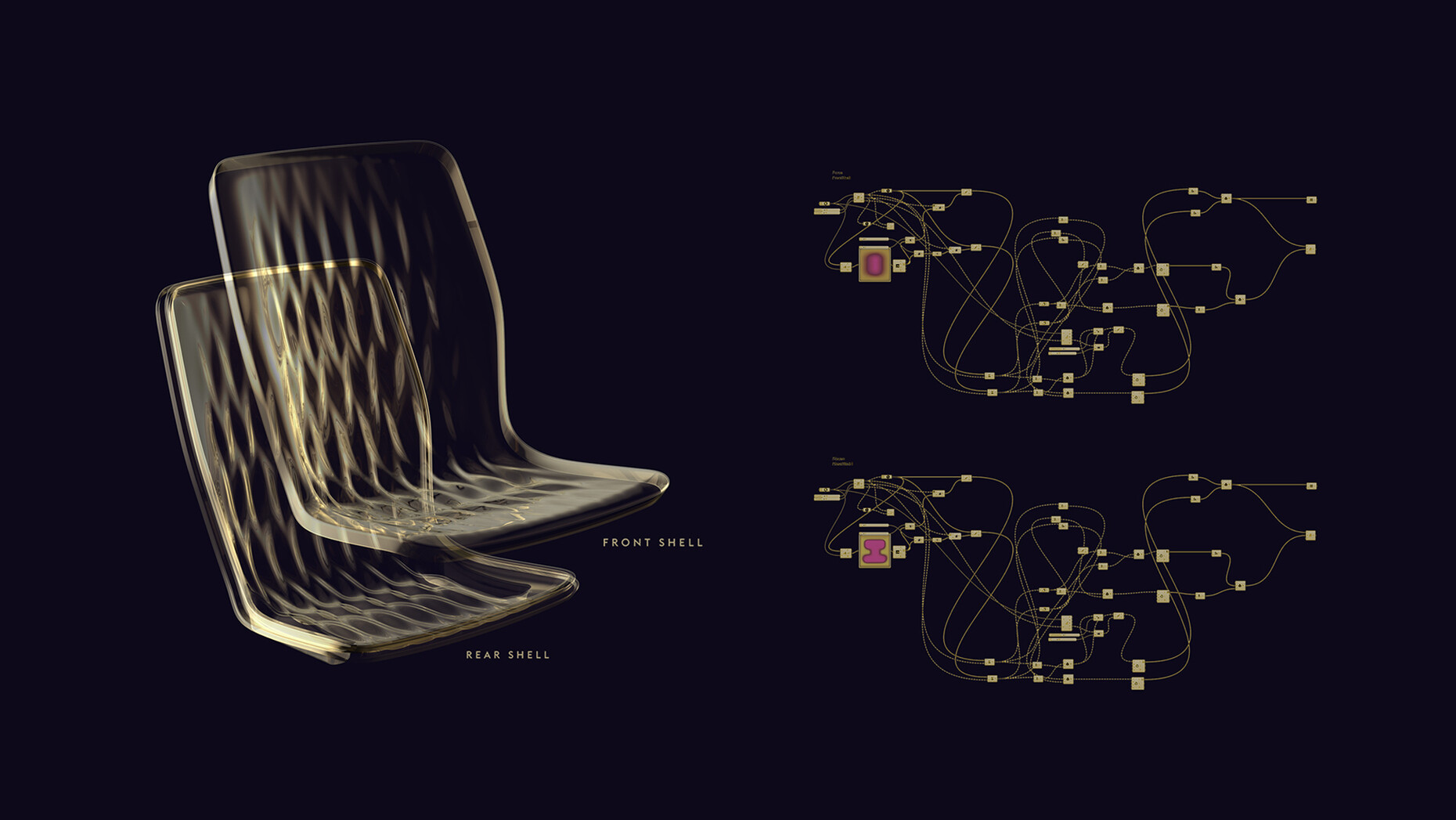

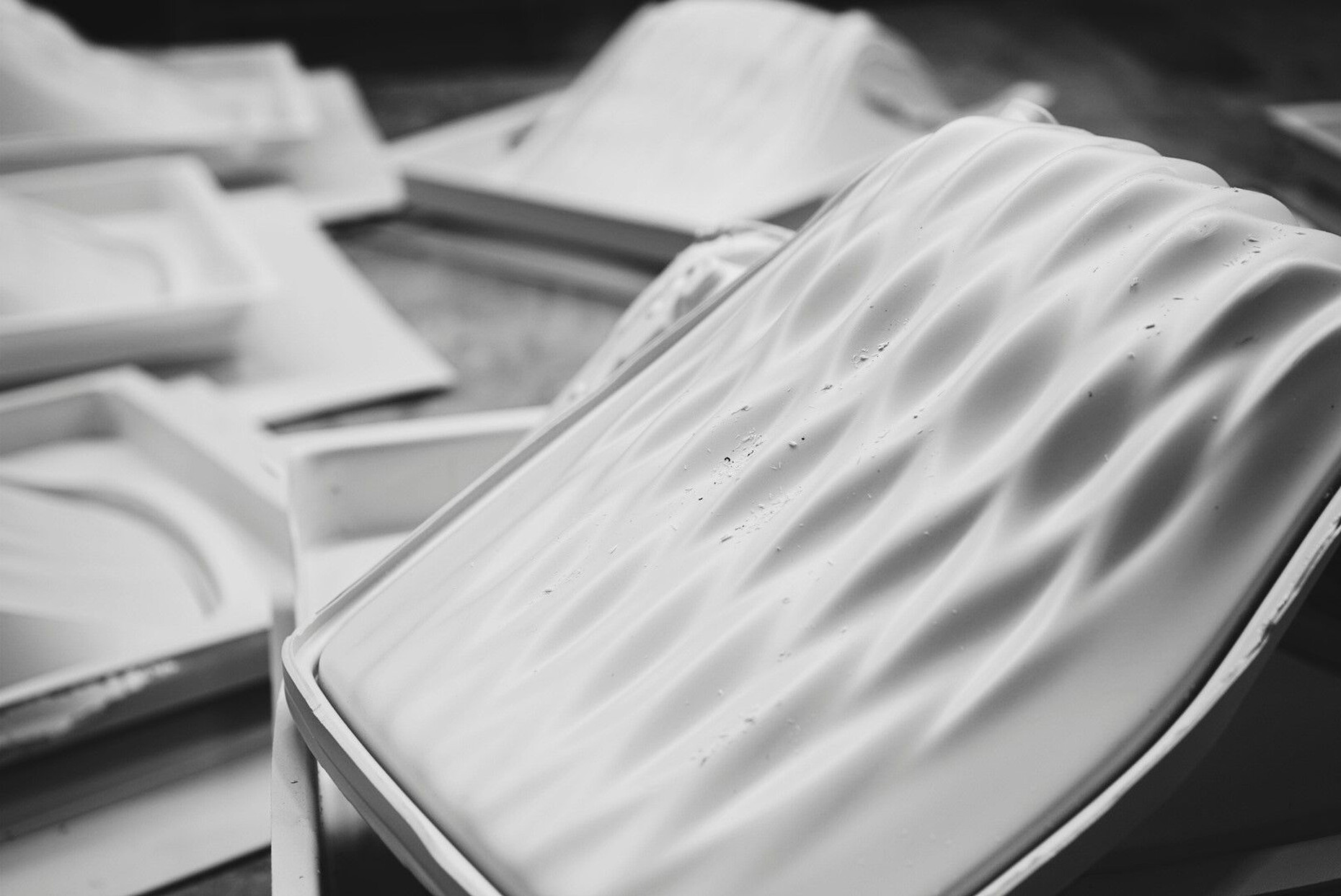

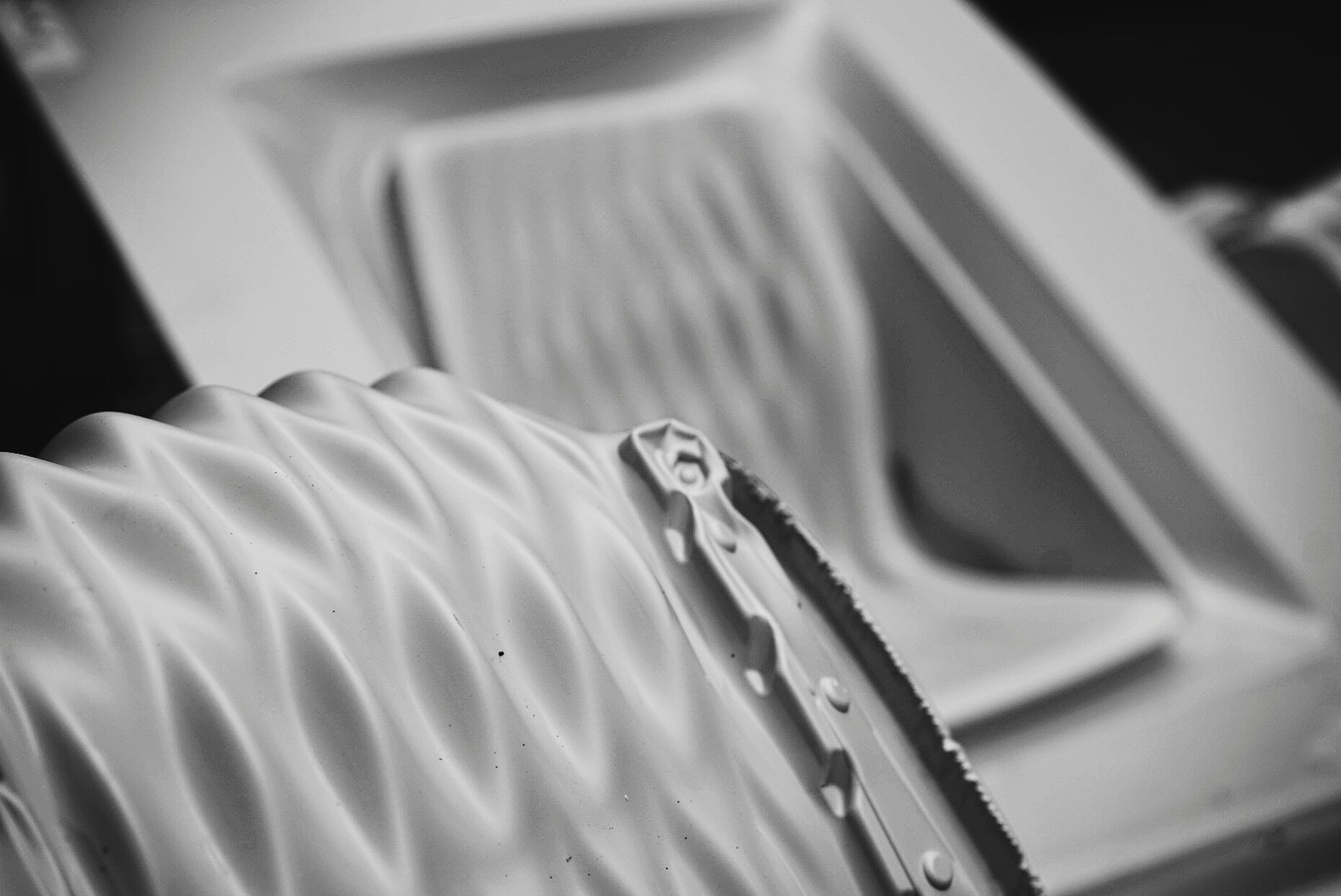

For the development of a lightweight seat, the industrial and product designers Christian Jurke, Dirk Licht and Dominik Meier, founders of the design studio NVGTR, together with their team created a design that was finalised using computational design - the structure of the seat is thus optimised with a specially programmed algorithm. The result is "Ubility Air", a robust seat shell produced using the twin-sheet process: Two sheets of recycled plastic are welded together into a mould using heat and vacuum; no other materials are necessary. "Material efficiency is the highest good," says Dominik Meier. Thanks to the ergonomic design, the lightweight seat also does without textile upholstery. Thus, the ultra-light construction with a complete weight of four kilograms saves both CO2 during production and fuel during transport and is recyclable. The project work was funded as an EU research project and by Grammer AG, which specialises in the development and production of components and systems in the mobility sector.

NVGTR is currently further developing the lightweight seat for the furniture sector: "We want to break with the paradigm in the design industry that only objects that are heavy have value. The resource-efficient approach also gives us freedom in design and offers a very unique elegance," says Dominik Meier. (am)