SUSTAINABILITY

Hydrogen as an energy carrier: reducing costs

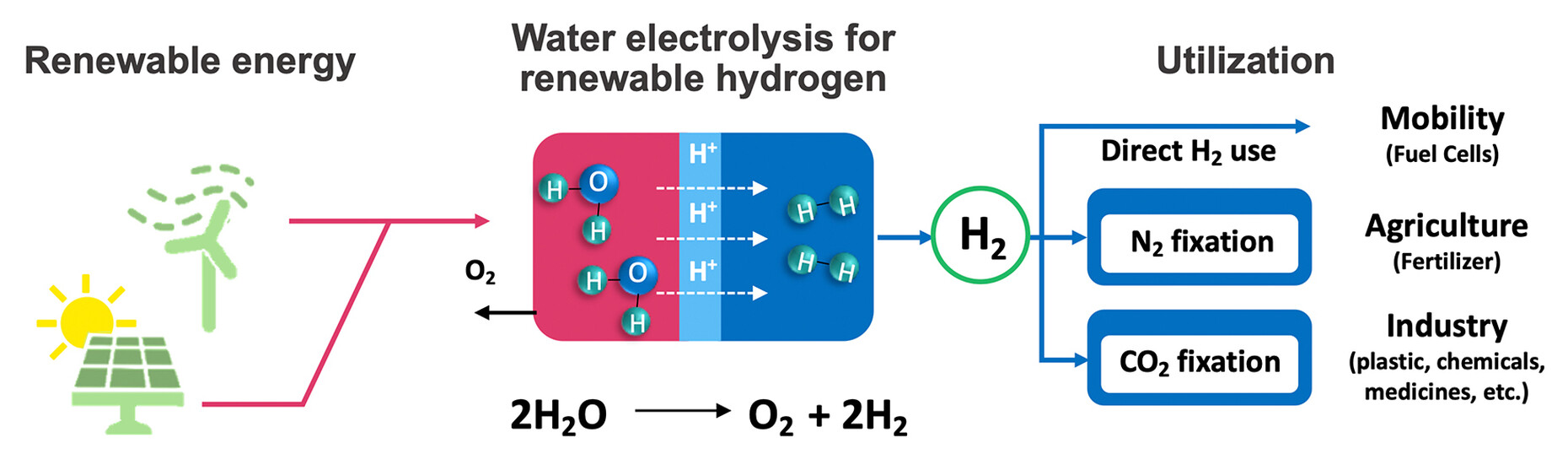

Hydrogen as a sustainable energy carrier could offer an important alternative to fossil fuels in the future - provided that the effort and costs for its production as well as the complex maintenance of hydrogen cars can be optimised. The expensive production process currently means that even in the creation of ammonia, which is used as the basis for synthetic fertilisers, the required hydrogen is not predominantly produced from renewable sources. "This is mainly due to the lack of good catalysts," says Nakamura. These are an important part of converting the chemical energy of hydrogen into a fuel: Water is split into oxygen and hydrogen in electrolysers with the help of electricity and catalysts. Until now, only rare precious metals such as platinum or iridium fulfilled the catalyst function smoothly.

As part of a study, researchers at the CSRS have now succeeded in replacing these with a mixture of two common metals: Cobalt and Manganese. The cobalt-manganese oxide is called "Co2MnO4" and, as a new noble metal-free electrocatalyst, represents a turning point in the production of hydrogen: "We have achieved what scientists have been denied for years: hydrogen production with a highly active and stable catalyst consisting of abundant metals. In the long run, we believe this is a big step towards a sustainable hydrogen economy. As with other renewable technologies, for example solar cells and wind power, we expect the cost of green hydrogen technology to come down in the near future as more progress is made," says Ailong Li of the Riken Center for Sustainable Resource Science. The next phase will be to increase the lifetime of the new catalyst and its activity. "We are aiming for a catalyst without rare metals that matches the performance of current iridium and platinum catalysts," says Ryuhei Nakamura.