Inventing stones

For decades, Godelmann has been offering a concrete block range that combines high manufacturing quality with sustainable production methods. This is evident, among other things, from the "Cradle to Cradle Certified Gold" certificate, with which the Bavarian company was the first concrete block manufacturer worldwide to be awarded. The fact that sustainable action is an integral part at Godelmann is shown, for example, by the construction of a concrete recycling plant at the beginning of the 1980s. In the meantime, 100 percent of unsaleable products or old pavers taken back free of charge are processed there in a specially developed recycling line. Added to this is sustainable water management, CO2-neutral production and the use of renewable energies.

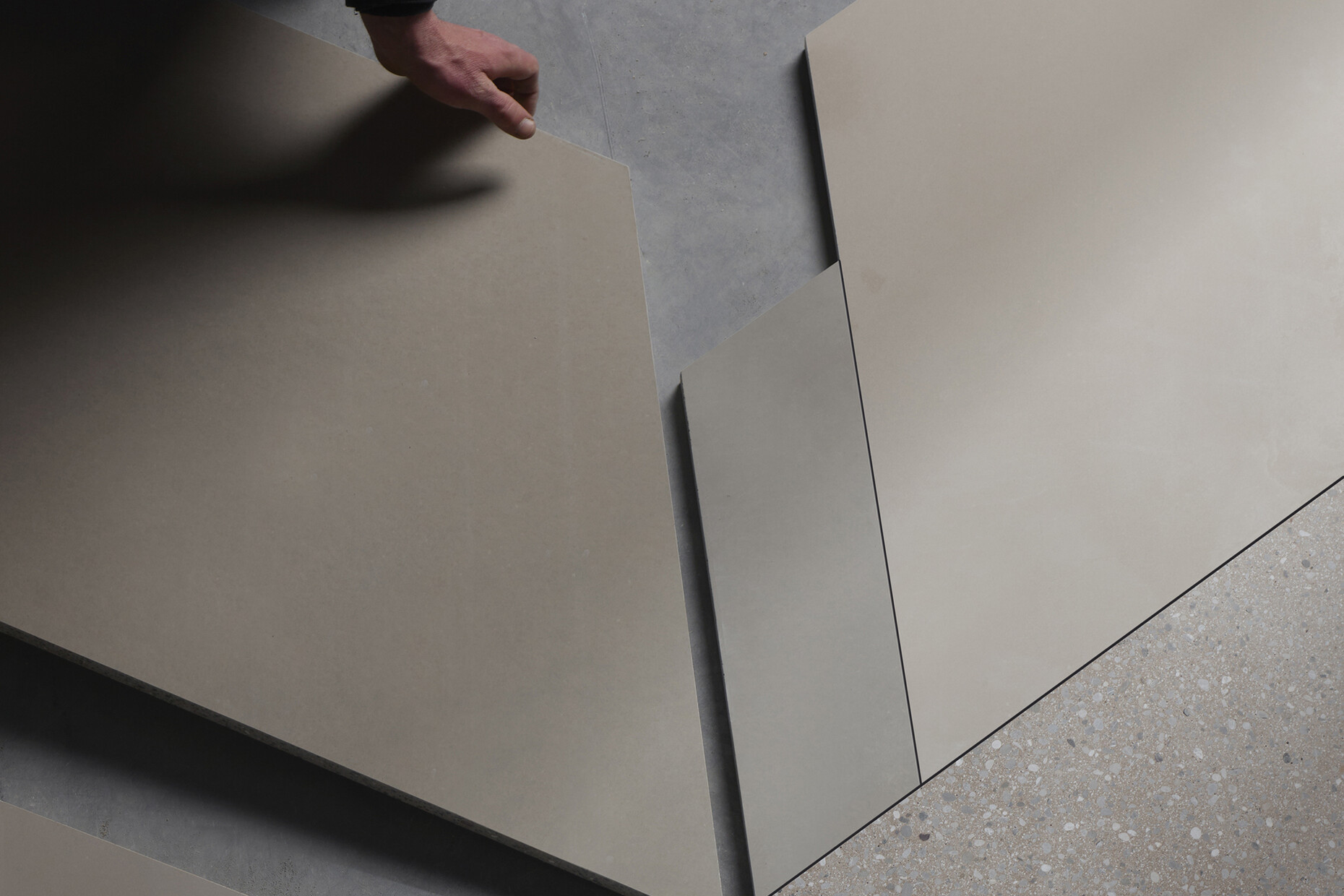

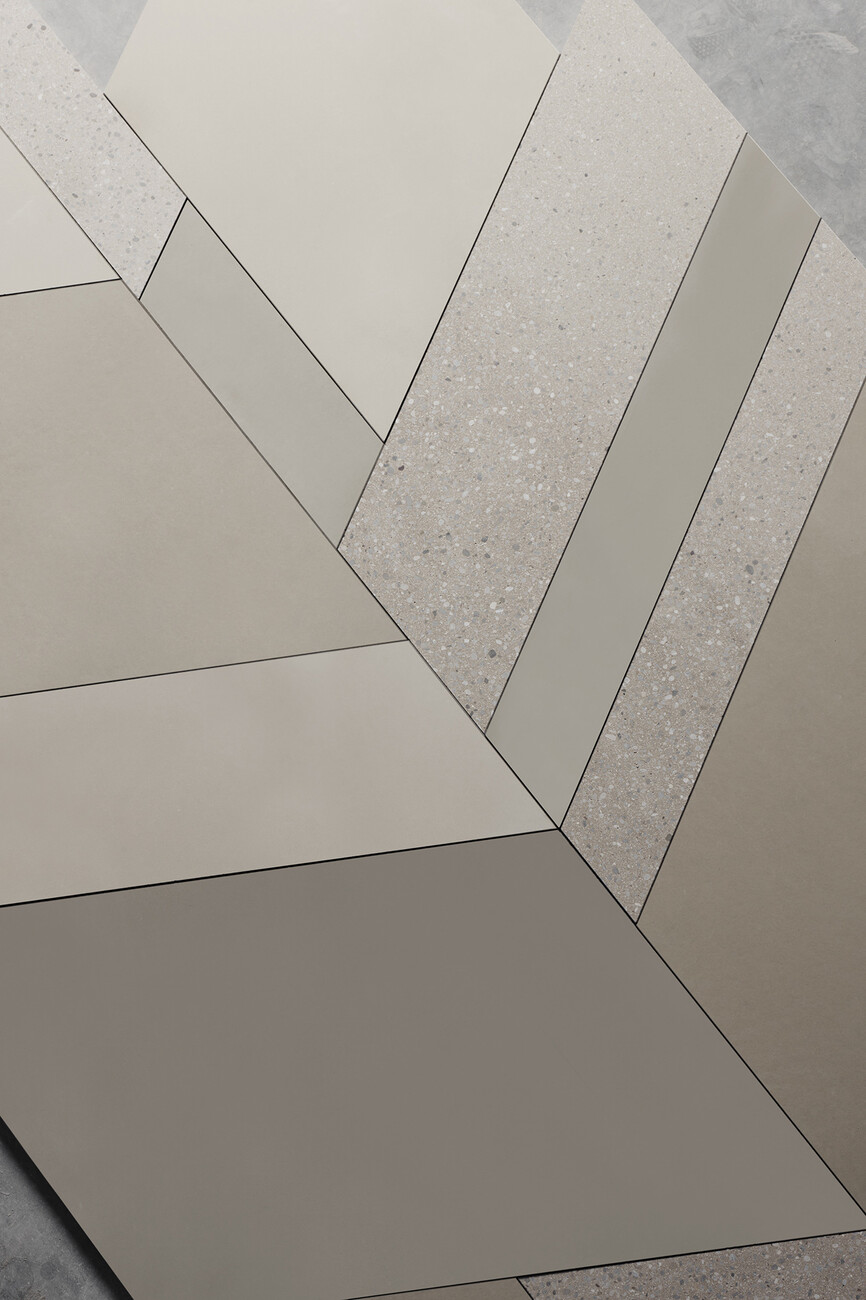

At the same time, Godelmann is also constantly breaking new ground in terms of design – for example in the form of so-called architectural concrete, a highly refined exposed concrete that can be produced in low material thicknesses while precisely reproducing textures on its surface. To this end, the company has now collaborated with designer Sebastian Herkner, who has developed a product line for both interior and exterior use. "GDM.AWA" is the name of the new architectural concrete collection, in which Herkner translated the look of a classic herringbone parquet into fine, velvety-looking and highly dense design tiles made of concrete. These are suitable for both floors and walls and offer a wide range of design options for both indoor and outdoor use.

For the product launch, "GDM.AWA" is available in six different sizes and four colors: sand beige, sand gray, silk gray and basalt gray. Each tile is weather-resistant, easy to clean and colorfast. "Concrete can be very diverse in color and texture – we want to show that. Each of the four color families therefore includes gradations of the respective shade, which can be combined with each other as desired," says Sebastian Herkner about the design concept. He also designed two terrazzo variants, each with aggregates of Weser gravel or Naab gravel, both of which are quarried in the immediate vicinity of the Godelmann plant in Fensterbach, Bavaria. These offer additional combination possibilities and complement the four color families with multi-layered textures. The individual exposed concrete tiles are handcrafted in Godelmann's architectural concrete factory. Each tile is poured by hand there and cures over 24 hours, while the terrazzo is additionally ground. The result is a multi-layered collection that can be used to elegantly link indoor and outdoor areas, creating new spaces.