SUSTAINABILITY

A Universal Principle

Prof. Dörstelmann and his team took their lead from nature with the design and manufacturing methods specially developed by them for innovative fiber-reinforced composite structures. And they consider the Texoversum in Reutlingen to be one of the projects of which they can be particularly proud. Moritz Dörstelmann explains the principle as follows: “In nature, all load-bearing structures are based on fibers and they achieve a particularly high material efficiency by arranging the fibers in a fiber composite material that is appropriate to both the load and purpose.” We are familiar with this from trees, which embed their cellulose fibers in a lignin matrix and reinforce their branch bifurcations to the extent where they are stable but, at the same time, do not use more materials than are absolutely necessary. This principle is universal and is repeated both in beetle shells with their chitin fibers and in human beings in the shape of our collagen fibers.

FibR, a company established by Prof. Moritz Dörstelmann in 2017, together with two schoolfriends of his, is now making full use of precisely this construction repertoire. To begin with, he spent seven years researching into digital technologies for lightweight structures for the building construction at the University of Stuttgart. At the time, his development work focused in equal part on the design and on construction technology. This work in an interdisciplinary team gave rise to a whole string of research buildings which impressively demonstrated the potential of this construction method and triggered a great demand for constructions of this kind. And Dörstelmann adds: “As an architect and researcher, I felt extremely motivated by the idea of being able to produce this type of structure on an industrial scale, one that had been tested as a prototype in an academic context, since it has allowed me to realize buildings that are utterly unique.”

One recently achieved milestone is the “Texoversum” in Reutlingen. This research and training building for textile research at Reutlingen University of the Applied Sciences is enveloped in 1,800 m² of a fibrous structure. This serves as fall protection for the wraparound balconies while also providing shading for the building’s fully-glazed façade. In this context, it was possible both to adapt the fiber density to the degree of shading required and to make do with the minimum quantity of material necessary to dissipate the wind and impact loads. The edifice fulfills a number of requirements for permanently weatherproofed outdoor use and fire protection stipulations, as well as providing a load-bearing structure and shade. Moreover, the building casts its own distinctive shadow. Another recently completed project illustrates the flexibility in manufacturing ceiling panels that are up to 2 x 5 meters in size; it comprises 2,000 m² of interior fittings with A1 noncombustible basalt-fiber composites. A third project currently at the planning stage is a load-bearing structure made of natural fibers for a restaurant. Something else presently in the pipeline is plans to add another story to a company HQ building using a fireproof basalt support structure. Besides this, interior fit-out made of flax fibers are in the process of being produced for a sauna complex and a six-floor atrium is being clad with a translucent fiberglass structure.

Optimized Fiber Meshwork

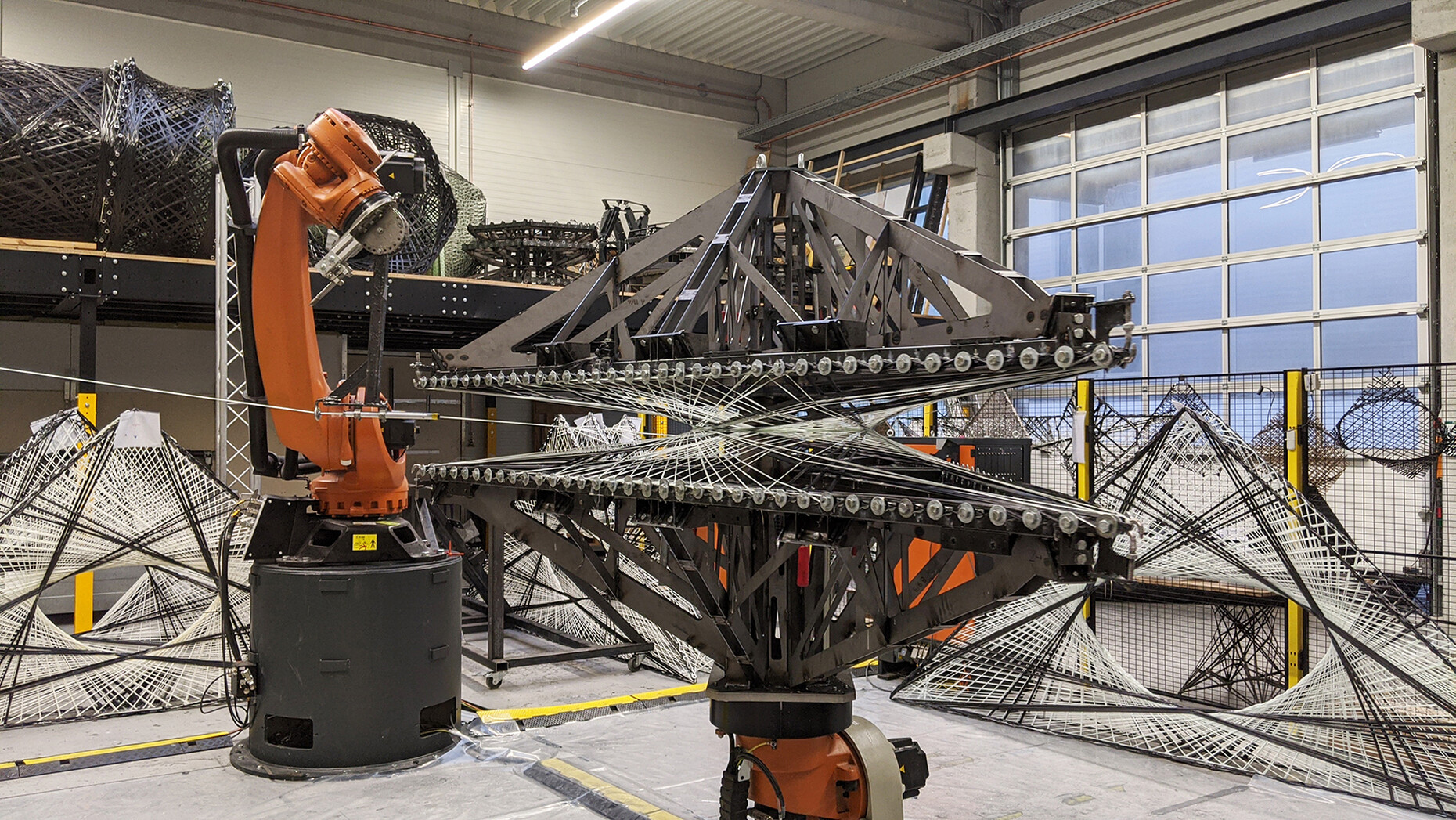

The entire process is based on spatially configuring the fibers using a computerized design process and a robotic manufacturing process. This technology could not be realized without digital technology and sophisticated software. “Nobody can manually draw thousands of different fiber orientations and in our case the process is computer-generated,” explains Prof. Dörstelmann. At the same time, design tools are used that make it possible to steer the process in cooperation with the project partners and the other planners, and to customize the system for specific projects. He then explains: “As is always the case with architecture, new construction methods are inextricably linked with discovering new design options, the kind for which we can use our digital design process to best effect. He continues by emphasizing that “unlike the situation with classic digitization in the construction industry, where work is conducted one phase after another, takes its orientation from existing processes, and does not, at the end of the day, result in construction methods that are fundamentally revolutionary, we have succeeded in making a breakthrough innovation possible in the building trade in terms of material consumption levels.”

Many different material systems can be used for the meshwork. For instance, projects are currently being realized with a biocomposite consisting of flax fibers and biopolymers which make for a particularly warm and natural appearance and are based on renewable resources. Carbon and fiberglass are also a very interesting option since they allow for structures that are very slender and, at the same time, extremely robust and capable of load-bearing. Overall, in terms of colors, FibR is available in any tone imaginable, and the structures can be executed in basalt fibers, for example, even in A1 (noncombustible). The materials can be used for a building’s primary load-bearing structure, in façade engineering, and in interior work. In this connection, all the materials can be used both in load-bearing contexts and for outdoor purposes that are exposed to the weather. At the moment, it is only the natural fibers that do not meet fire protection requirements. Glass and basalt fibers are made of molten sand or volcanic rock. Currently however, the fossil-based fibers are still considerably cheaper.

Primarily, FibR sees itself as a component manufacturer, that is to say, as a company that handles part of the building’s execution. The team collaborates closely with the developer and the planners, architects, construction engineers and interior designers to enable the lightweight building technology to be meaningfully integrated into the design and planning process. It offers services across all stages of the process chain; everything from conceptual studies, prototype development, permits, implementation planning, construction design, and even the production and assembly of the components on site. Because the fibers are configured in such a way as to support precisely a particular load, this method of construction allows for the material requirement to be minimized without any reduction in load-bearing capacity. A classic concrete beam with a dead weight of around 11 tons can thus be replaced by an equivalent made of lightweight structural linen mesh that weighs only around one ton. “With material and energy costs on the rise and business conditions generally adjusting, our extremely resource-saving construction method makes us considerably cheaper than using conventional techniques,” explains Prof. Moritz Dörstelmann.