PREVIEW – SALONE DEL MOBILE & MILAN DESIGN WEEK 2024

Relax emphatically

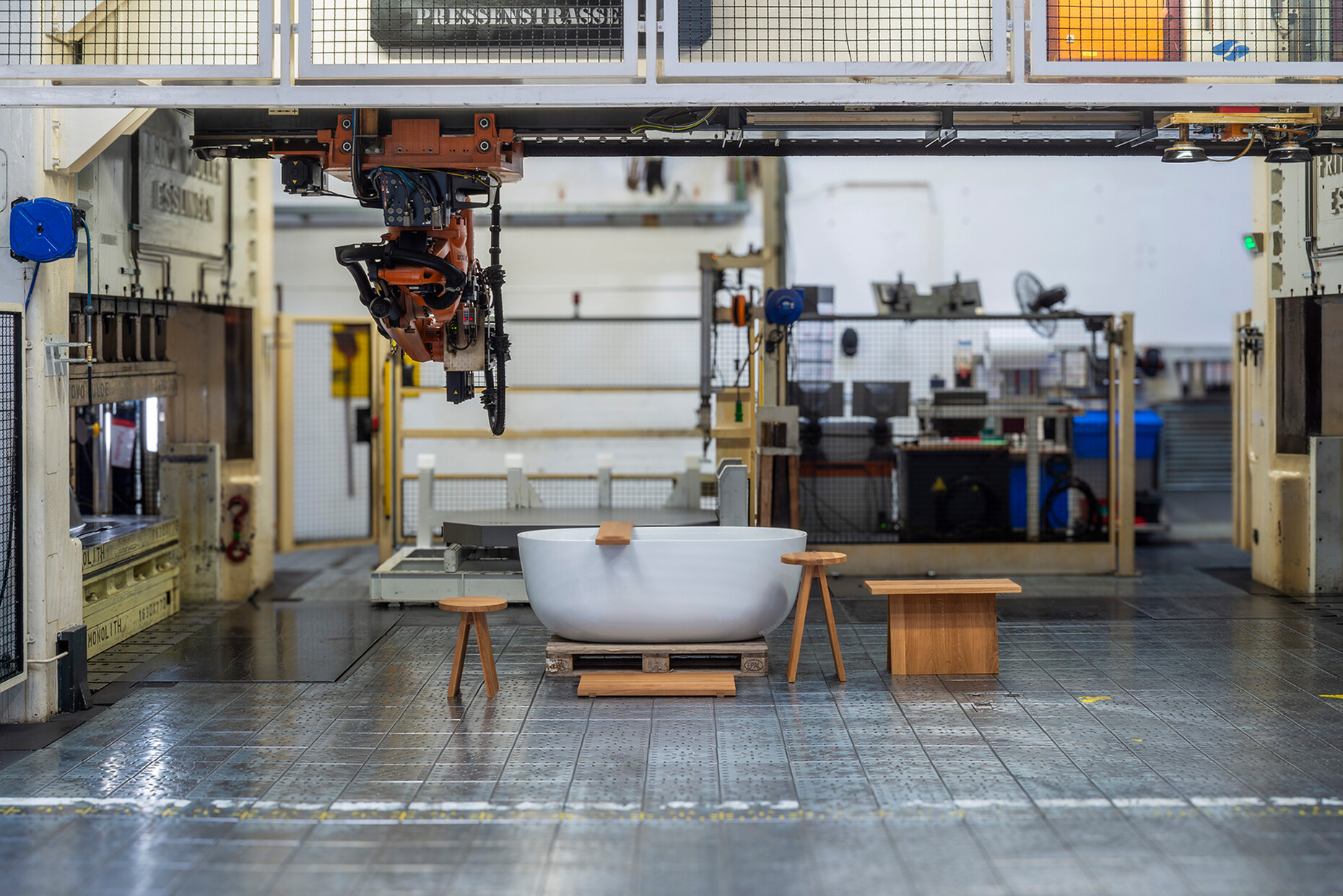

At the beginning of last year, bathroom specialist Kaldewei unveiled “Oyo Duo”, a free-standing bathtub with steel enamel cladding that Stefan Diez designed for the company’s exclusive “Meisterstücke” product line. Not only its double-walled design and seamless surface make it special, but also the organic lines forming an elegant oval fashioned from steel enamel – something that is unique to date. And thanks to the two identical sloping backrests and central drain the bathtub can also comfortably accommodate two people. The space beneath the bathtub allows it to be installed without a screed recess as the drain fittings can be flush-mounted in the bathtub body.

For the new “e15-Kaldewei Collection” the renowned designer has now brought e15 into the bathroom: The collection includes two stools of different heights, a bench, a footrest, a magnetic bathtub tray and a towel rail. In addition, the collection includes accessories of water-repellant leather by Sorensen, a spacious bag and towel loop in the colors ‘Ecru’ and ‘Elephant’ that can be fixed to the edge of the bathtub with magnets. All the shapes have a clear, archetypal appearance, no element is unnecessarily complicated, and no screws are used for the wooden furniture. The high quality of the stained oak speaks for itself as does its subtle appearance making it suitable for many different contexts.

In 2009, Stefan Diez designed the “Houdini” chair for e15, demonstrating even then how expressive wooden furniture can be. “e15 is a company with a very consistent language. All our designs have character. It took 18 months to develop the 'e15-Kaldewei Collection' because designing something that seems simple is the most difficult thing of all,” says Stefan Diez. The products have already passed the endurance test in the climate test chamber where they were exposed to 100 percent humidity and 70°C for a whole week without a break. The oak wood proved to be entirely resilient. Another benefit of using oak is that the wood’s natural tannic acid makes the surfaces perfectly hygienic. “Kaldewei is a remarkable brand with impressive manufacturing methods and many years of experience. e15 and Kaldewei share many values. Both companies stand for pioneering design, high-quality materials, and sustainable production. As such developing a joint collection was only natural,” explains Philipp Mainzer, designer and founder of e15.

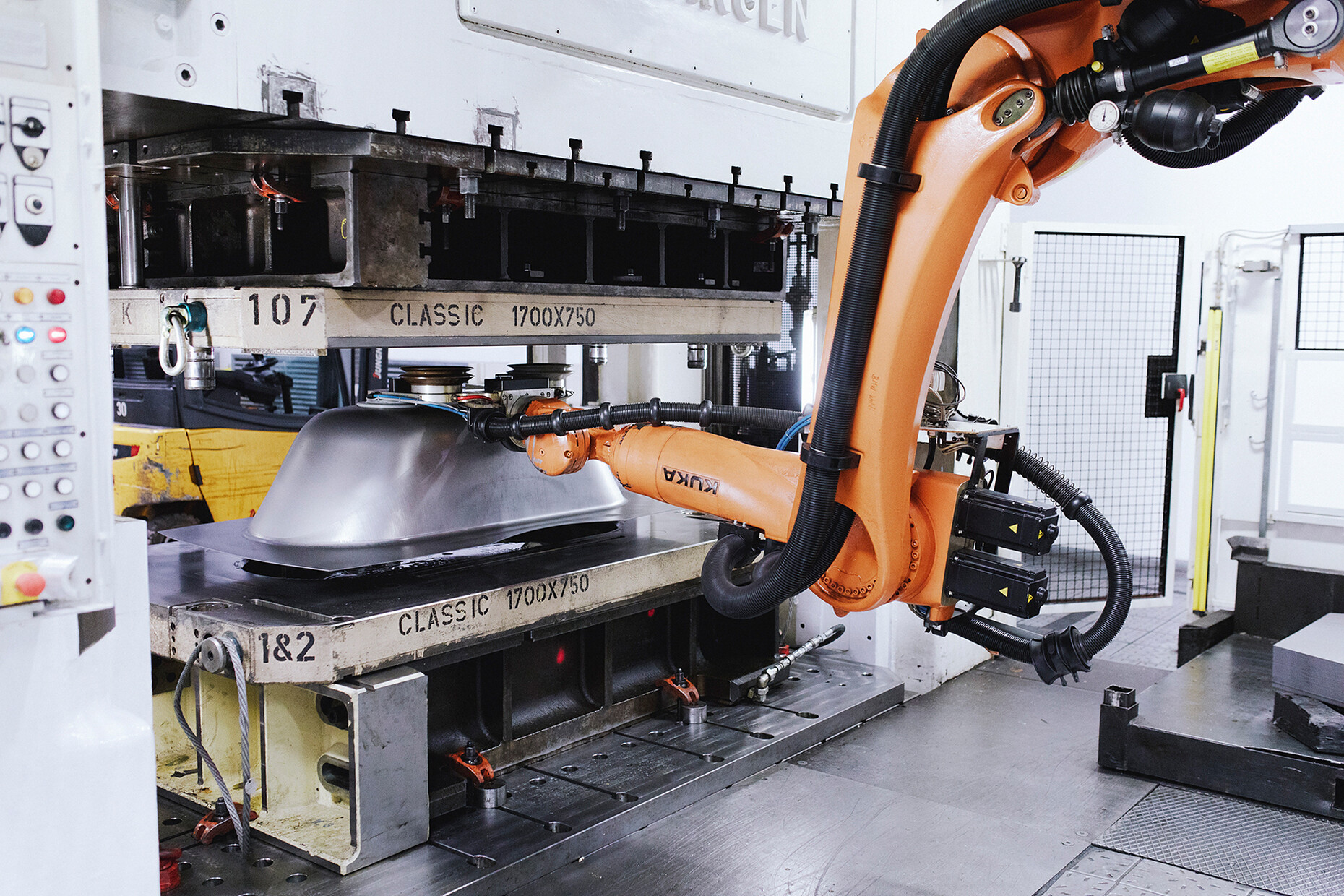

Kaldewei, e15, and the Diez Office are united by their high standards of quality, craftsmanship, and environmentally-conscious working methods. Kaldewei’s way of producing things allowed for a particularly impressive example of this triad: “My collaboration with the company began with a visit to Kaldewei in Ahlen, where every step of the production takes place. For me as an industrial designer it is amazing to be able to see the heart of Kaldewei, because it’s wonderful to work with a partner who has this great expertise,” says Stefan Diez. Kaldewei’s steel-enamel which is also used to line the “Oyo Duo” bathtub makes this product especially robust: the black-and-white glass granulate for this is made separately in the company’s own enamel ovens. Kaldewei is the only manufacturer worldwide to have come up with the ideal mixture of minerals, iron ore and sand itself. Some 430 kilos are produced in one batch. The transport system runs no less than 13 kilometers through production, starting with the pressing lines where the shapes of the bathtubs, shower trays and washstands are pressed into the steel sheets under high pressure. This process produces a rumbling and groaning sound that booms through the hall and accompanies the robotic arms’ ballet-like choreography. The arms move the steel elements from A to B, cut off protruding edges, weld suspension tabs to the molds and apply two layers of enamel. Shortly afterwards, things get hot as the products are transported into the oven where the steel and silicate glass bond at 850°C. Depending on the model, anti-slip surfaces can be applied by hand on request.

Many in-house developments are used in production, from coating through to tools. Kaldewei also produces small series and special models. At the end of the production line every bathtub, shower tray and washbasin is checked by staff down to the last detail – one of the basic requirements for being able to offer customers a 30-year guarantee. The final stage involves transportation to the distribution center where countless bay shelves extend up to the ceiling and create deep, dark corridors. Sorting processes and onward transportation to the packaging and logistics stations are largely automated with up to 300,000 products regularly passing through the system.

With the “e15-Kaldewei Collection” Stefan Diez and e15 have created an ideal new addition to Kaldewei’s bathroom products, which like the steel enamel is produced carefully and sustainably. The collection is made from European oak wood – a high-quality, sturdy material for which the team came up with a pared-down, architectural design suitable for every setting: The two angled legs of the “EK01 Stools” with a round seat and the “EK02 Bench” with a rectangular top converge in a connecting element. The “EK05 Base” footrest and the “EK04 Bridge” bathtub tray with a round side recess for a towel are also understated and unusual in both design and thickness of material. It is held in place on the bathtub by a magnet. Every product in the collection is handmade in Germany. The “EK06 Pocket” and “EK07 Loop” of sustainably tanned leather also ensure you have all the necessary paraphernalia to hand for bathing. Kaldewei calls the concept

“Luxstainability”, a term coined from combining the words luxury and sustainability. The “e15-Kaldewei Collection” makes it clear once again what is behind the term: high-quality, circular design reduced to the essentials .

e15 at Salone del Mobile

Hall 24, Stand L05

Fiera Milano, Rho

16 – 21 April

9.30 am – 6.30 pm

e15 – KALDEWEI

Casa Flash Art

Via Durini 24, Milan

16 – 21 April10 am – 6 pm