Visionary in Things Water

“My father once said that if we make something new it must be practical and look good,” says Yvonne Dallmer. A holistic view which marries form and functionality. This attitude is extremely important particularly in the field of sanitary systems since, once one has been installed, it is intended for permanent use over as many decades as possible. Consequently, every product in Dallmer’s wide range of drainage solutions is correspondingly sustainable. The variety of shower drain channels ranges from distinctive solid stainless-steel models to colorful ones with PVD coating and invisibly tiled solutions. This makes for a large number of different individual varieties in terms of color, shape and positioning in the shower. From the very outset, this family-run company has been known for the pleasure it takes in inventing new solutions. In 1913, Yvonne Dallmer’s great-grandfather established a small artisanal workshop which initially specialized in engraving work. At the end of the 1950s, the next generation started producing its first plastic articles, enthusiastically spending more time tinkering with ideas for new drainage solutions. Lead fell into disrepute as a raw material because of its damaging effect on health and was replaced by industrially produced plastics such as Bakelite. However, getting plastic into the desired shape using injection molding did represent a challenge. Dallmer tackled this problem, developing the first plastic siphon molded from a single piece and including a 180° bend. This innovative product was shown at the second ISH, the world’s leading trade fair in Frankfurt am Main, in 1963 – and laid the foundations for the direction the company had traveled in ever since.

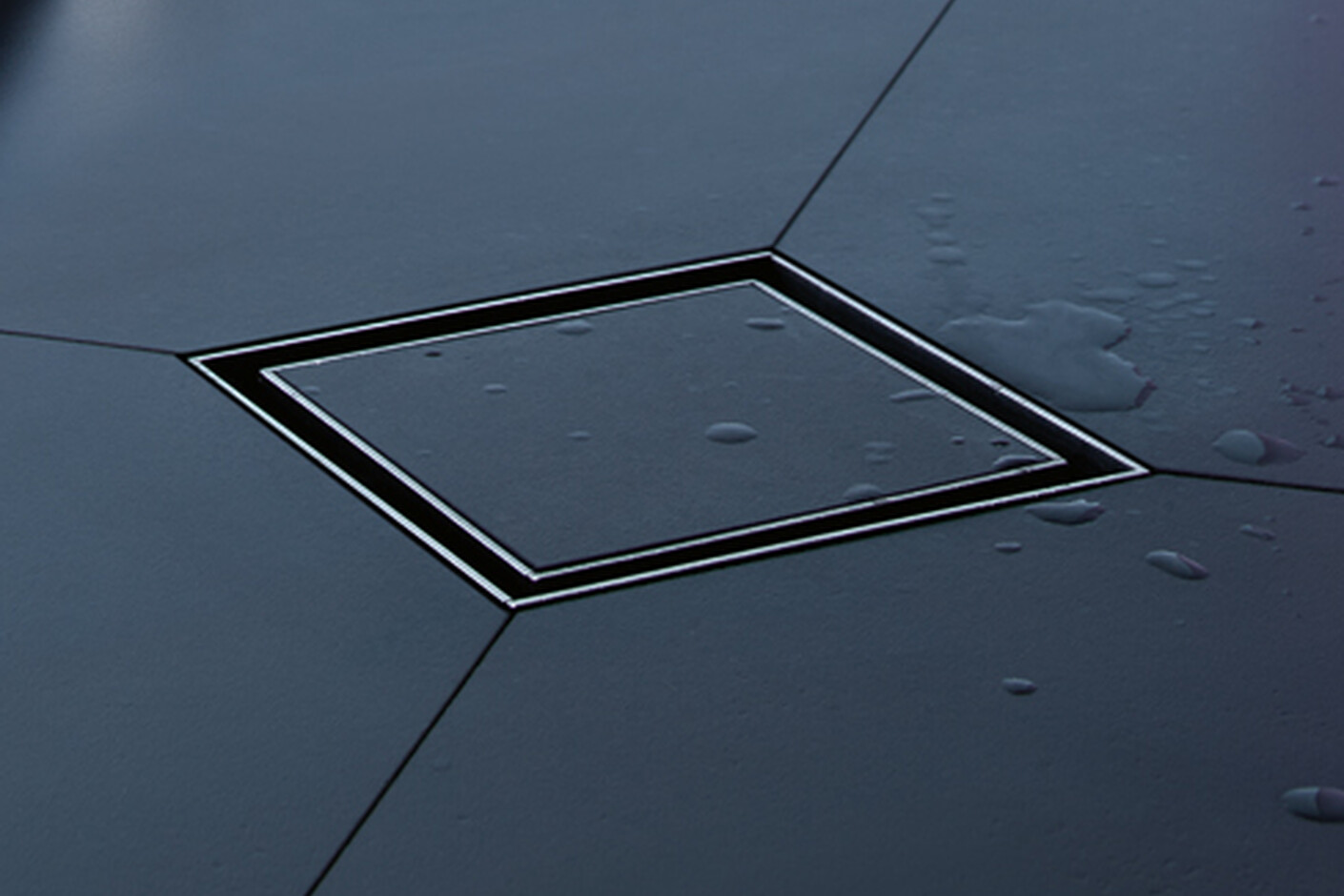

Starting out as a component supplier in the field of household-related services, the firm thus developed, within the shortest imaginable time, into a specialist in drainage systems. Further pioneering work was to follow: At the end of the 1980s, Dallmer presented its first “CeraDrain” floor drain for compound seals. With a polymer concrete flange the drain guaranteed the greatest possible stability and a secure installation, ideal for sanitary ware, which is subjected to heavy wear and tear. “It is the details that make the difference,” comments Yvonne Dallmer. However, the trend away from the functional washroom to the bathroom as a living space also prompted innovative thinking at this specialist in drainage systems. Around the turn of the millennium, “CeraDrain” was joined by the first designer drain channels – a meaningful alternative to the point discharges that had been the predominant solution until then. “With our designer drain channels it was our aim to offer new and appealing aesthetics in the bathroom,” explains Dallmer.

In 2013, to mark the company’s 100th anniversary, they launched “CeraWall” which, for the first time, separated the shower channels from the drain in level-access showers right at the installation stage, thus allowing for surface-guided drainage. The starting point for the new “DallFlex” system family is the drain body or shower element onto which all nine different Dallmer channels can be fitted. Another unique Dallmer product offered for the new generation of its “DallFlex” system family is the precast gradient, something which considerably facilitates the installation of the drain. Something completely new in the Dallmer range is the “DallDrain” floor drains which offer a suitable solution to all kinds of installation situations and come both in entire sets and as modular parts. At the same time, with every new development the focus is always on customer service, with Dallmer providing its products, which are manufactured exclusively in Germany, with a full ten years’ guarantee.

Part of a team

For all the successes of the past 100 years this family business has never forgotten its strong roots. “When we need new component suppliers we always start out in our own backyard,” explains Yvonne Dallmer. Many of the staff are also rooted in the region, have a sense of belonging to the company and remain associated with Dallmer for years, as she explains. Flat hierarchies, great flexibility, a real team spirit and permanent investment in modern equipment all make for consistently high quality standards. Major plus points which become particularly apparent in the somewhat stormy economic conditions of the pandemic. “We want to share success with our staff, to cultivate know how and to develop passionately,” she summarizes. Dallmer has been managing the company together with her father, and engineer Harry Bauermeister since 2008, the fourth generation of the family to do so and, after spending many years abroad, she gives it an international perspective. “We are guided by a great desire to be innovative,” she explains.

What is characteristic of Dallmer in this respect is its focus on the manufacturer and the user instead of the competition. The company’s in-house development and construction department comes up with the kind of practice-oriented solutions that are guaranteed to be easy to install and maintain, as well as not being dependent on short-live trends. In order to find out where our products can become even better, we are in constant dialogue with our users,” says Yvonne Dallmer. To step this up, as of December 2020 Dallmer is launching its “Dallmer Sessions”, hybrid training courses for architects, planners and skilled tradesmen. The comprehensive program they offer will consist of seminars, online training courses and videos. “With these sessions, our aim is to extend our training program and pass on our knowledge. We want to communicate the idea behind our products and to give people a helping hand with the kind of standards and applications that they encounter currently,” explains Sebastian Kellermann, Product Manager and Head of the Technology/Support Department at Dallmer.