The new super-materials

Lighter, stronger, cheaper or sparing more resources, this is the goal. Composites are the new super-heroes of the world of materials: multifunctional and more efficient. Consisting of at least two different elements, these materials possess better properties than the individual components underlying them – or even feature new qualities. Today, composites are omnipresent in the world of architecture and design. Manufacturers and researchers are chiseling away at new and optimized combinations. We took a closer look at some of these new and highly-promising composites.

The art of imitation

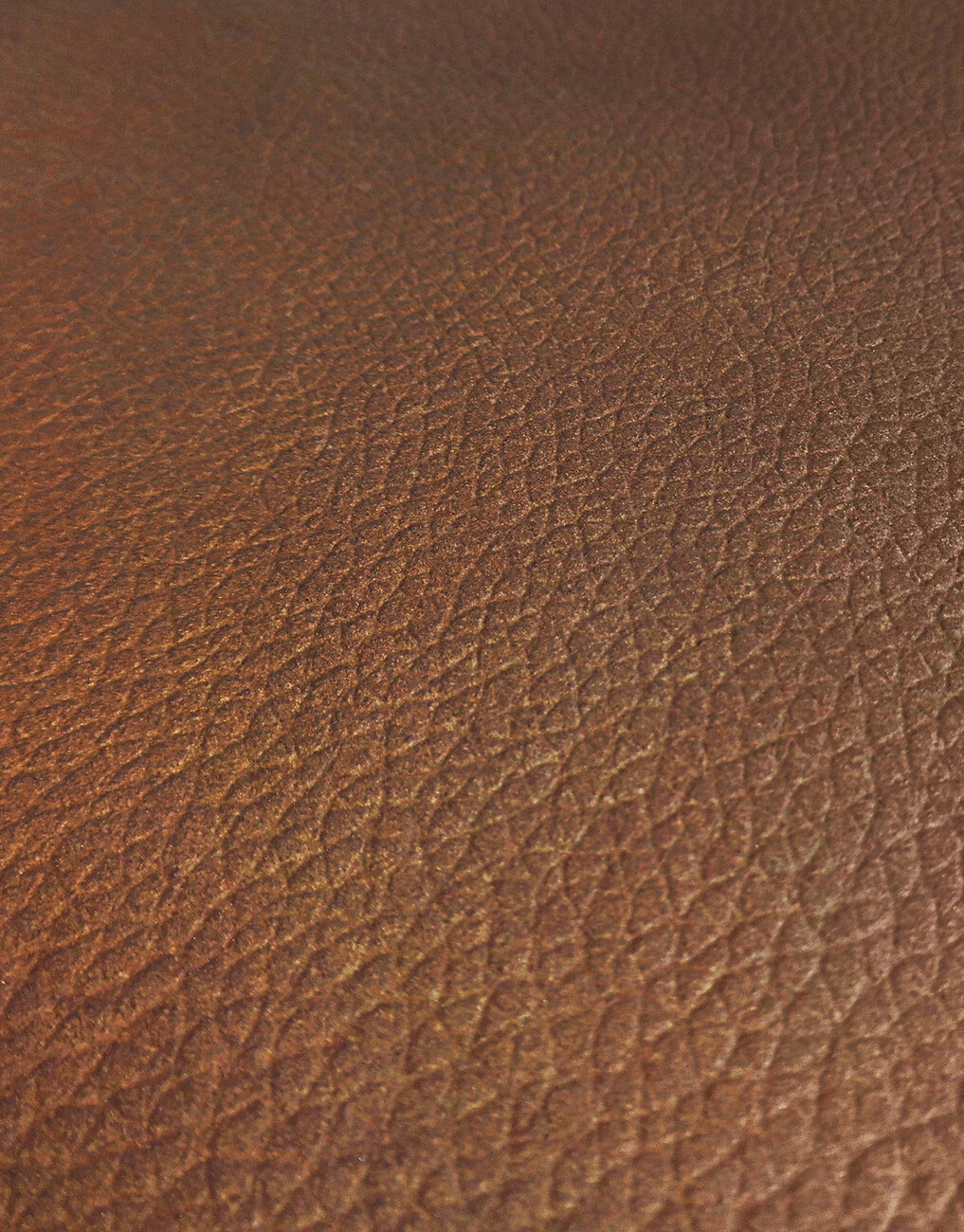

In the field of interiors, the trend is to deploy deceptively genuine imitations and surfaces. Stone, wood, or leather, for example, can now be imitated so well that even experts don’t notice the difference at first sight. Leather is a material with a high-grade effect, but that is expensive and hard to procure. Imitation leather is therefore in all the more demand for furniture and fit-outs, both fields taking their cue from the fashion world here. As the high-grade appearance and pleasant tactile properties can long since be achieved without using animal products.

“imi-Leder”, for example, the latest development from Schubert, not only feels real, on request it can even smell like real leather. The backing consists of light composite panels that can be worked using conventional carpentry tools. This imitation leather is ideal for store and interior fit-outs precisely because it is so simple to process and can be used for large surface areas.

Things are even simpler if the desires material can be “painted” onto wood or MDF board. The series of special-effect paints by Chroma Lacke imitate the look of marble, silk or even leather, enabling a great diversity of surfaces to be created, and even the haptics and textures resemble the originals. For example, the surfaces that can be achieved to emulate a variety of leathers feel soft and elastic thanks to a “Soft Touch” lacquer. By contrast, the silken effect creates a soft, velveteen haptic and the marble effect emulates the use and grains of the high-grade material.

While natural materials age gracefully and over time gain a quite appealing patina, imitations often do not. Anyone who wants nevertheless to enjoy that special traces left by Father Time can in fact use a composite. The new composite panels made of “Alucobond Vintage”, for example, look like rusty steel, oxidized metal, copper with verdigris, or weather-worn concrete – patina for the impatient as it were. The composite panels consist of two aluminum sandwich sheets and a polymer core and again boast a special lacquer coating that can not only imitate materials but also how they age.

Refined use of off-cuts

Another important theme: the production of composites from regenerative materials such as plant fibers, coffee grounds, pine needles or hay for example – or recycling waste and surplus products. The growing volume of textile off-cuts, for example, prompted Danish manufacturer Really to come up with its “Solid Textile Board” and “Acoustic Textile Felt”. The one is destined for furniture production, the other for use as acoustic paneling. Both composites consist 70 percent of fabric waste from laundries and off-cuts from the Kvadrat textile company. This are chopped up and using a thermoplastic binder turned into granules that can then be pressed to form boards. The “Solid Textile Board” can be bent and its surface treated in various ways. British designer Max Lamb recently showed in Milan just what can be achieved using this eco-friendly composite – with a series of different benches. Since manufacturing requires no dyes or toxic chemicals, the composite can be recycled and go back into use.

“Corcrete” is a concrete featuring a recycled cork additive that thus not only relies on a recycled material but also on a regenerative one at that. The composite was developed by Germany’s Design Studio Niruk. The cork concrete panels are suitable both for furniture-making and as cladding for walls or ceilings. The special additive means they are lighter than conventional concrete, baffle noise and have a softer, warmer surface feel, as the cork becomes noticeable when the surface is sanded.

An artificial stone is made using a similar principle – its heyday was actually back in the 15th century in Venice, but for some years now it has been very popular again. Terrazzo is now available in more eye-catching and modern color combinations and materials thanks to the efforts of makers such as Dzek or Terrazzo Project. Classic additives are gravel, or fragments of marble or glass. However, designer Conor Taylor for London-based Foresso, thought up something new. His “Timber Terrazzo” is a deceptively real looking imitation of the classic types. What looks like artificial stone from a distance turns out to be a composite of fine woods and a resin binder. The wood additives are actually waste products but receive a new lease of life with “Timber Terrazzo”.

The next level

While composites are becoming more efficient by combining the benefits and properties of two or more materials, and even generate new properties, smart materials respond to their surroundings and can expand a particular material’s properties. The plan many have is to render composites smarter going forward, for example by including sensors that respond to temperature or tough, change their degree of hardness, by equipping them with LEDs.

While the fields of medical technology and mechanical engineering have made many an advance in this area, research in architecture in this regard is still in its infancy. So it will be exciting to see what potential composites will offer in the years ahead.

Interzum

Furniture production Interiors

Koelnmesse, Cologne

May 16-19, 2017