Featured

Individual and sustainable

Robert Volhard: Olivier, you have been with the Hansgrohe Group since 2016. What do you think makes the company special?

Olivier Sogno: An enthusiasm for water and for all the products that can be given to architects and designers to create the best possible project.

Hans Grohe founded his metal spinning business back in 1901, producing affordable sheet-metal showers. As a trained cloth maker, he thus took a very successful leap in a new direction and had a significant influence on future shower culture. He was 82 when he invented the shower rod. Is that courage to keep trying new things still evident in the hansgrohe and AXOR brands today?

Olivier Sogno: The chronology of constant additional advances is something that hansgrohe and AXOR have been able to continue through from those beginnings right into the present, with the basis being the guiding principle of optimizing the status quo. Innovation is the first thing you associate with hansgrohe, immediately followed by design, particularly ever since AXOR was established as a design brand in 1993. The third thing is the quality of our work. Quality informs everything we do – because every person on our team makes a contribution to meeting our customers’ expectations. Added to which, for a few decades now sustainability has been ingrained in all our operations.

The former three-man operation has grown into a company with almost 6,000 employees. To what extent would you say this success can be attributed to the structure of the family business – to this day Richard Grohe remains a member of the Supervisory Board as a representative of the founding family?

Olivier Sogno: The connection to the founding family is always there, but even more important is how decisions are made and how the communication channels work within the company. Very short decision-making paths, very personal decisions, communication and proximity – for me, that’s what defines the quality of a family business.

Among other things, we have just seen the legendary “TriBel” mixer by Hartmut Esslinger, aka “frogdesign”, in the product exhibition. Like him, his former colleagues Andreas Haug and Tom Schönherr, now “Phoenix Design”, also played a major role in hansgrohe introducing “good form” to the bathroom world from the late 1960s onwards. How did the collaborations with these big names come about?

Olivier Sogno: Our collaboration with Hartmut Esslinger began even before he started working for Apple. The designers you mentioned all came from Stuttgart, so local networking was easy. At the end of the 1960s, both sides had an entrepreneurial zest, they both wanted to create something; they understood each other, and that’s how it started.

A good 30 years ago, Klaus Grohe was already saying, “Climate change is not a distant future, it’s reality. The whole of society needs to contribute to reducing cabon emissions. We are setting the course for beyond tomorrow.” It was for this and other reasons that the Hansgrohe Group has just been presented with the German Sustainability Award. How has the company been plotting its course for sustainability recently?

Olivier Sogno: We are committed to the 1.5-degree target of the Paris Climate Agreement. Our actions are firmly geared towards the wellbeing of the planet, as is also expressed in our mission statement, “In touch with our planet.” Furthermore, we’ve set up our very own “Green Company Program” with ten initiatives. This includes supplying all sites with green electricity. By 2025 we aim to use only plastic-free packaging, and by 2030 we want to have equipped every water-bearing product at hansgrohe and AXOR with water- and energy-saving technology.

Within the Hansgrohe Group there is a “Green Company” section headed by Steffen Erath and Rebecca Weigold – what are its tasks and goals?

Olivier Sogno: Steffen and Rebecca and their teams are driving the ten initiatives we mentioned before, but the successful transformation into a “green company” can only succeed if the green mindset, the awareness of sustainability in the company, is anchored in every team member, from procurement through to product management. A major contribution to this comes from the Innovations Lab – many of the product solutions for a more sustainable future originated here and in product management. Parallel to this, we are talking to designers about how, for example, we can reduce materials inputs right from the design stage. This also applies to presentations at trade fairs – if you set up an exhibition booth once and then throw it away, that’s not sustainable.

In line with this sustainable approach, you developed an exhibition booth for the ISH this year that consisted of scaffolding poles and can be reused many times.

Olivier Sogno: That’s precisely the idea. But there is also a dichotomy: Should we reuse the same exhibition booth, or do we give in to the idea of showing something new? We believe we can do both: exhibit something new and reuse something at the same time.

Given the company’s high sustainability standards, this question doesn’t really arise, does it?

Olivier Sogno: That’s exactly the conclusion we reached ourselves. We have decided that our priority is to reuse booth. For us, the “show” is not so much the exhibition stand, but rather the innovations we present to our customers.

At the last ISH you presented the “Green Vision Beyond Water” among other things. What’s the status quo of this concept study?

Olivier Sogno: The idea was to develop a vision for how energy and water consumption can be reduced in future. As the underlying principle for the design, you need to start with the overall picture, which is what the “Green Vision Beyond Water” offers. The idea was to develop a vision for beyond tomorrow. To implement this, we are now working on realizing individual elements.

And of course, you want to take the opportunity to reveal what they are, right?

Olivier Sogno: Not yet! (Laughs) All I can say is that it is easier to change the technology and reduce resource inputs than to change people’s habits.

There are also cross-connections – for example, if you halve your water consumption when showering, you also cut the energy required to heat the water.

Olivier Sogno: Exactly, this connection is relevant to the fittings, too. With “AXOR One”, for example, the products have been designed in such a way that they start with cold water, because if you’re just washing your hands, you don’t necessarily need hot water. With the shower head, we have managed to significantly reduce water consumption by using a different type of spray (PowderRain) without compromising the showering experience. We are also working on further innovations for this and other collections.

The days of the purely functional “wet room” are long gone – what is the significance of the bathroom in people’s lives today?

Olivier Sogno: For AXOR, the bathroom is a haven of wellbeing to which people can retreat. We see the bathroom as a “low-tech area” where the digital world has no place.

The AXOR brand teamed up with designer Philippe Starck to create its first bathroom collection in 1994 and at the same time stage the modern living bathroom – the Salon d’Eau. Starck is an unconventional free spirit, yet developing sanitary products means taking account of numerous directives. Why does the collaboration work so well regardless?

Olivier Sogno: You said the key word yourself: collaboration. It’s not one creative mind alone. We can offer the bespoke technology, the designers come up with the creative ideas, and the result is the best of both worlds. In addition, Philippe Starck, Antonio Citterio, and Barber Osgerby, to name just three designers, also know a great deal about installation technology and its use, as they generally also work in architecture. They are also customers of ours for their own projects and know what works in practice. Together we figure out the best solution. If we are able to implement an idea immediately, that’s generally an indication that something is too simplistic, that we need to take a closer look.

With its products, AXOR offers a broad range of different versions for individual bathroom and kitchen scenarios, as in the form of the “Make it yours” campaign. Why do we need this large selection?

Olivier Sogno: I think one of the reasons why many architects and designers appreciate AXOR is the depth of our range. In other words, with one collection they can cover many different situations in the bathroom, and that makes the design easier. And if we are unable to realize a vision at any point, we see that as an incentive. With the “AXOR Signature” service, however, we generally find a solution that is as individual as the customer’s signature – in terms of color, material, surface, engraving, or length.

As far as prices and availability are concerned, AXOR offers maximum transparency – from the very first unit. Why is that?

Olivier Sogno: In the luxury segment, you also have to be able to design a product uniquely in line with the motto “Make it yours”. With our products, we give our customers the freedom to realize their own ideas for their bathroom.

The Hansgrohe Group guarantees 15-year availability of spare parts – five years longer than required by law. Why?

Olivier Sogno: The sense of quality and sustainability is anchored in the company’s DNA. Our products boast substantial longevity, and we need an extended spare parts guarantee to match that.

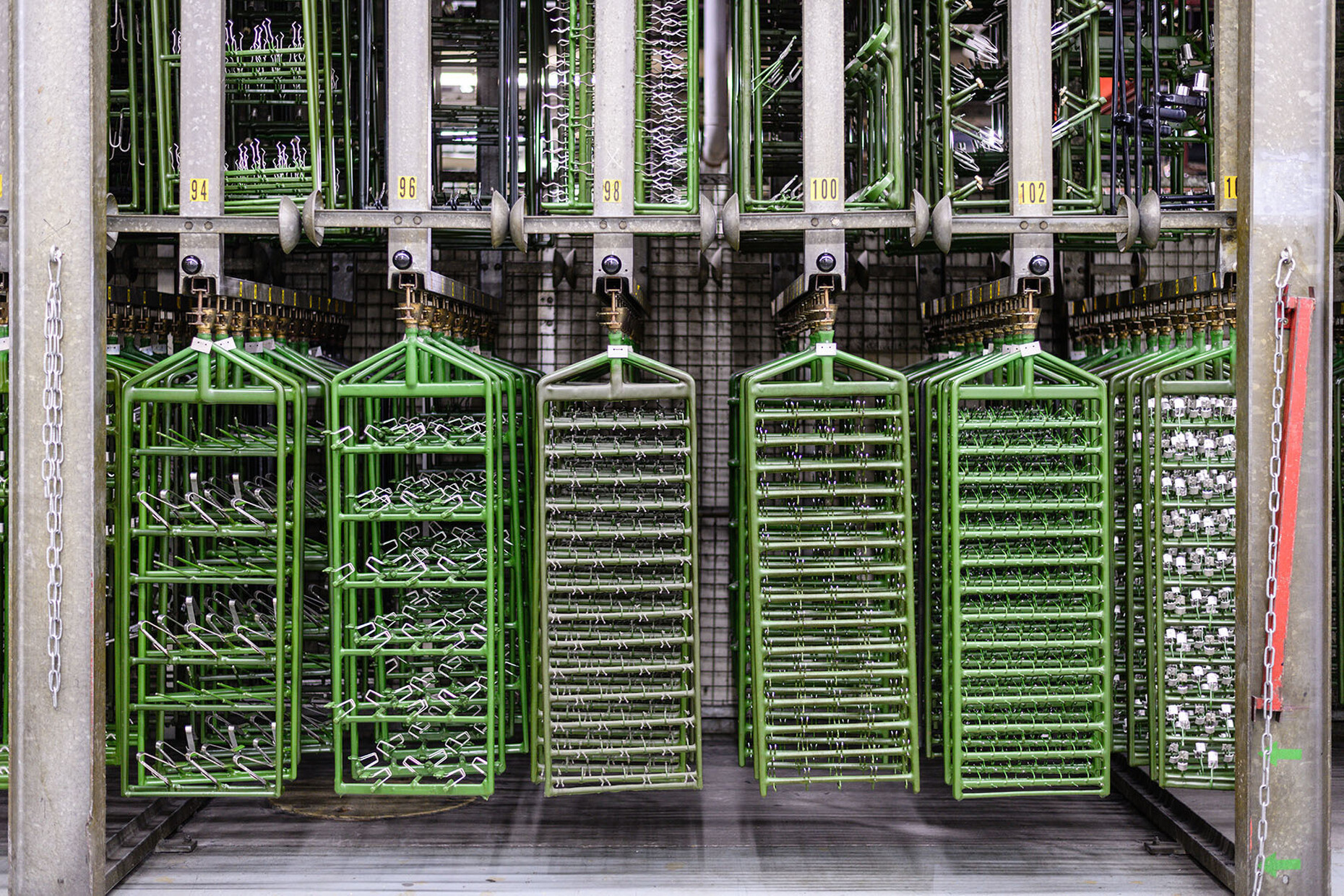

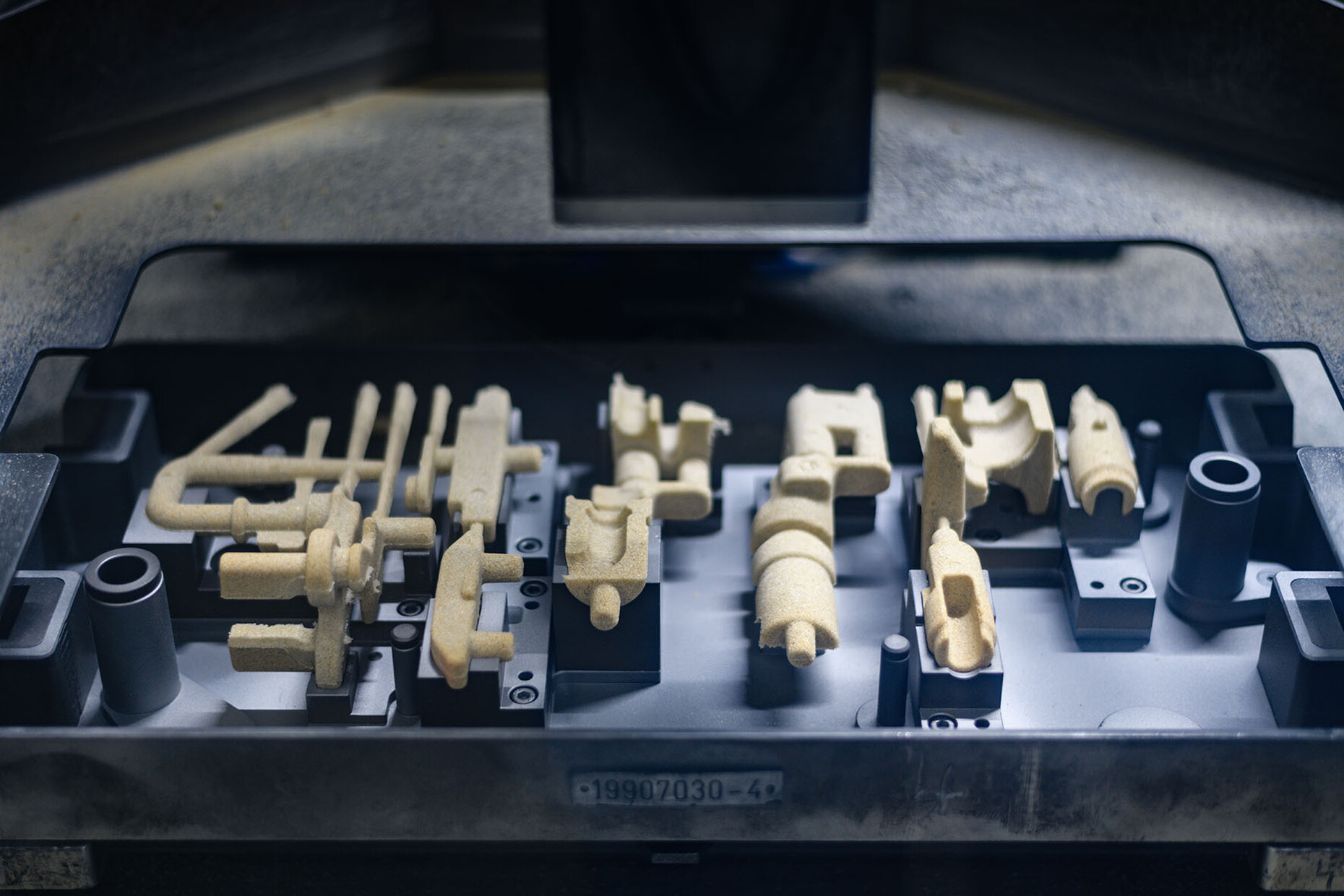

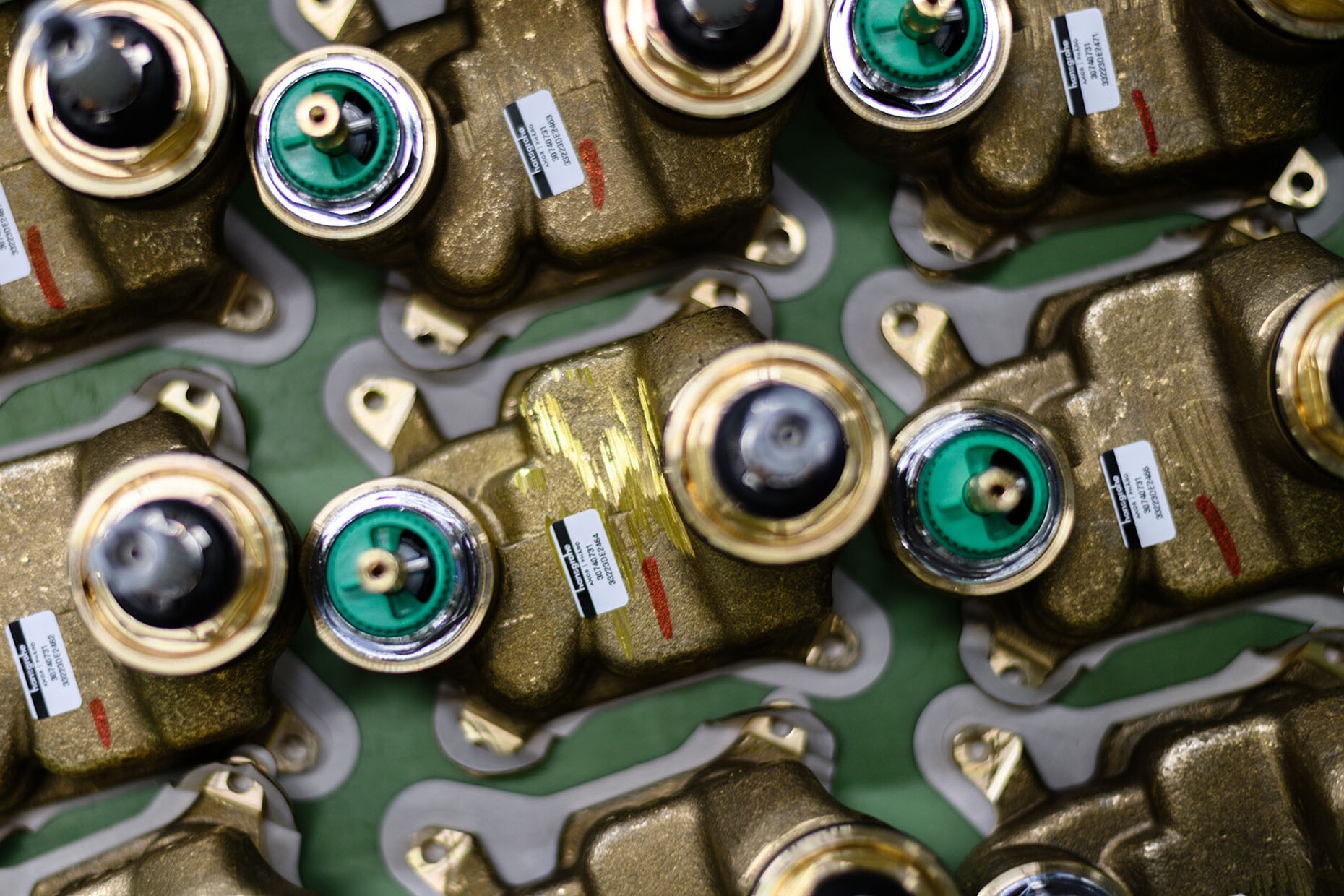

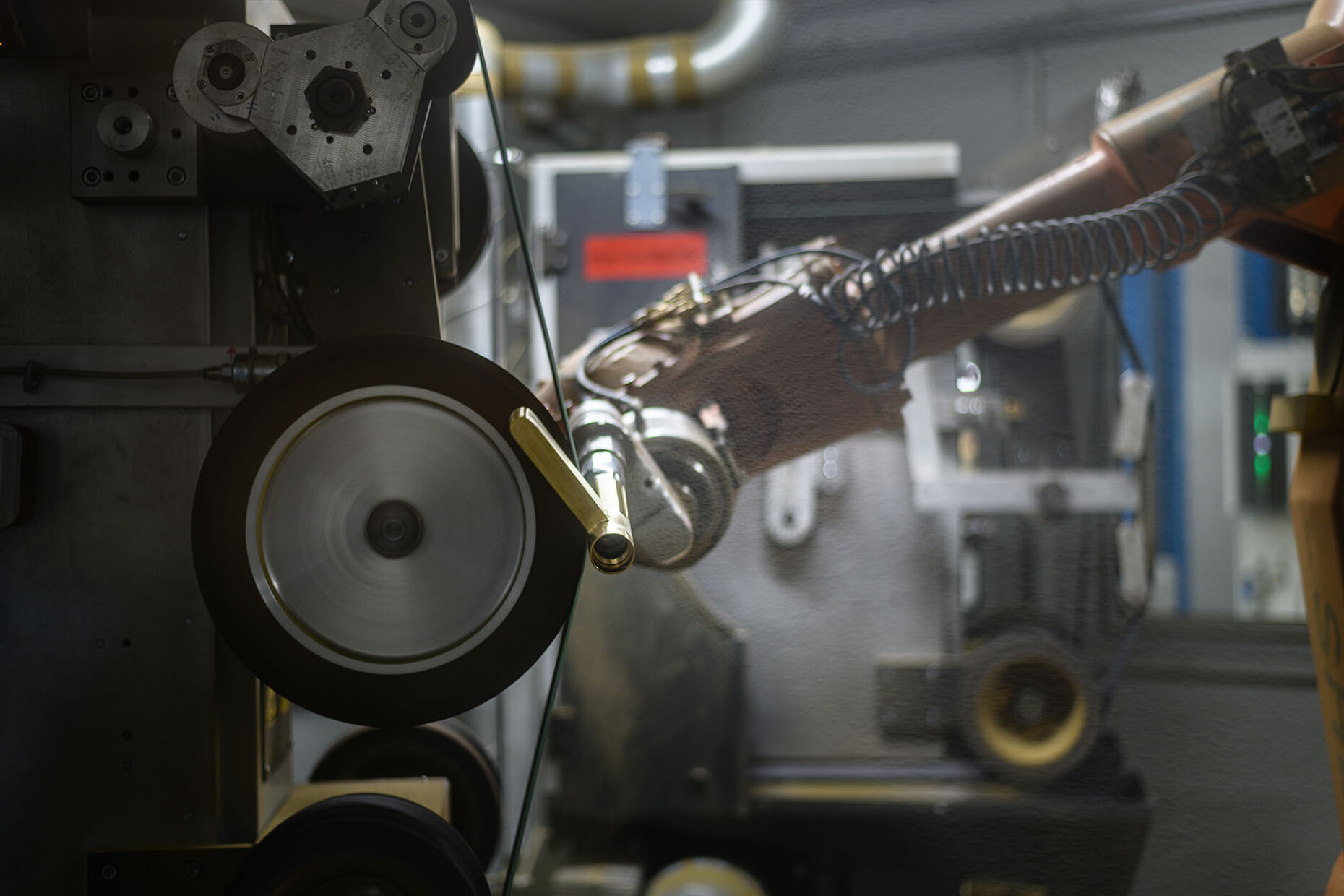

The “AXOR Center for Excellence”, i.e., the product site in Schiltach in the Black Forest, has recently been extensively modernized at a cost of 12 million euros. What effect has this had on the product range and logistics?

Olivier Sogno: With the primary goal of better meeting customer needs, we have invested heavily in automation and redesigning the flow of goods to increase capacity and shorten delivery times. Since the beginning of the year, for example, we have been able to offer an availability of six weeks for all colors and combination options and to strengthen the good relationship we have with our customers through this reliability.

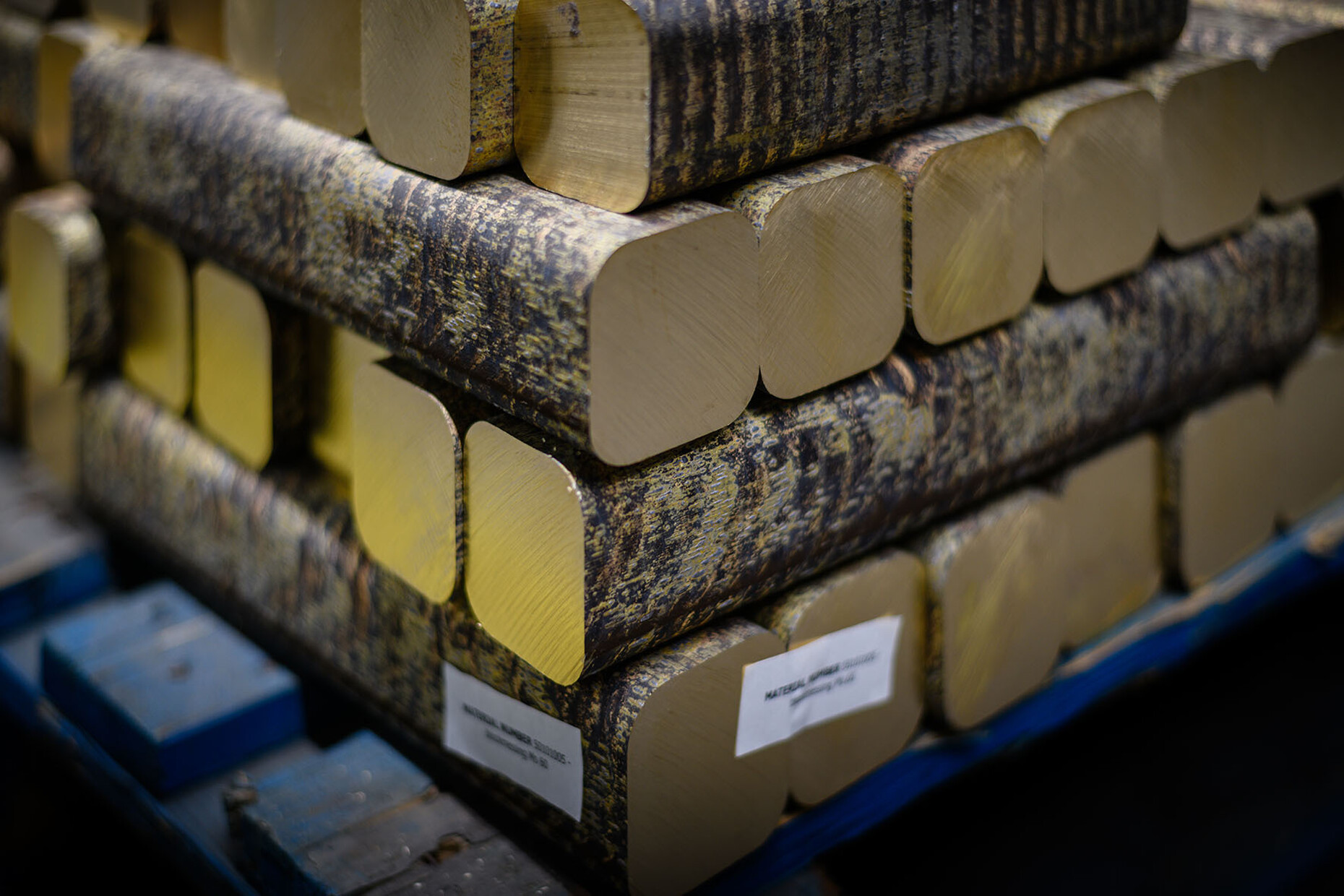

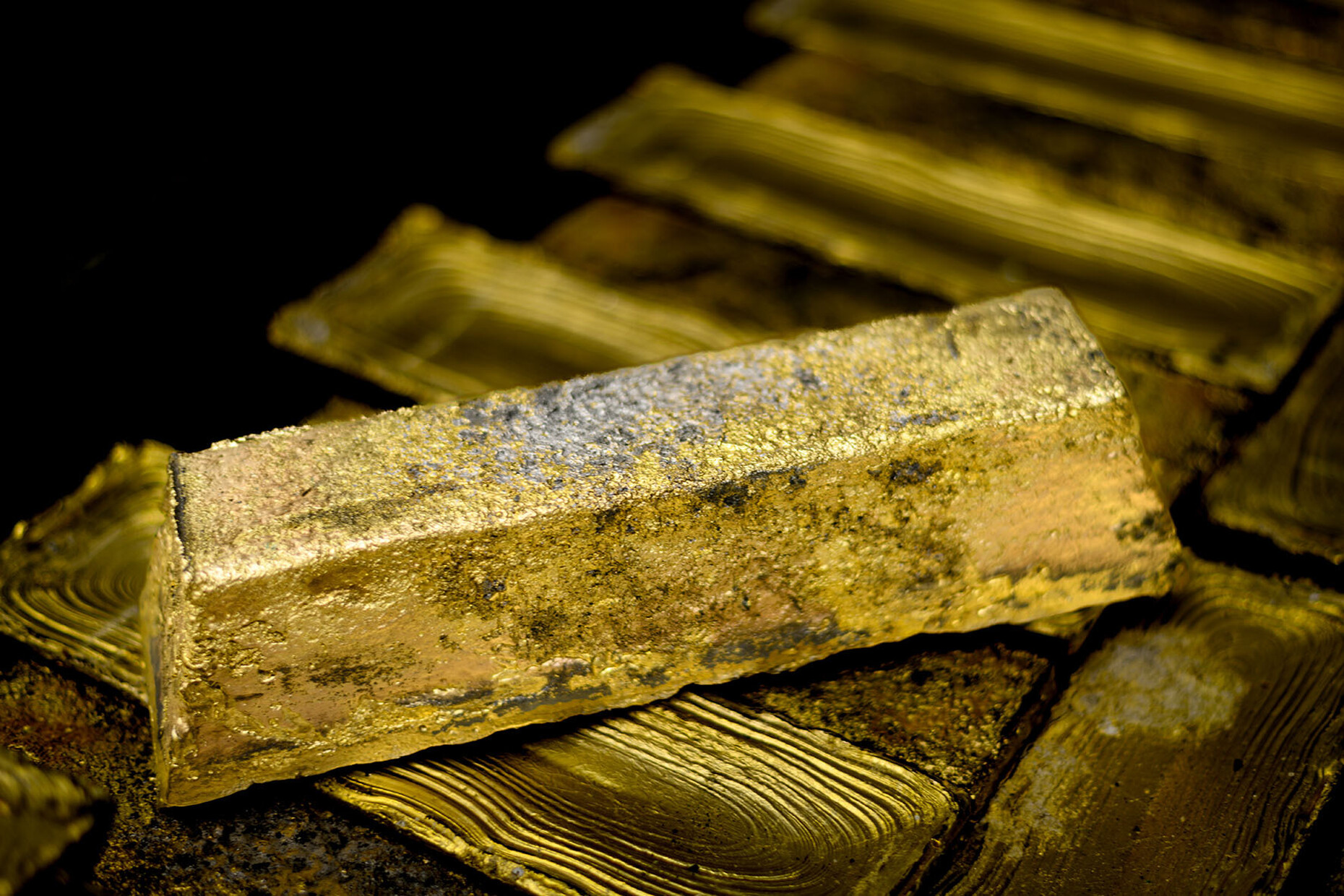

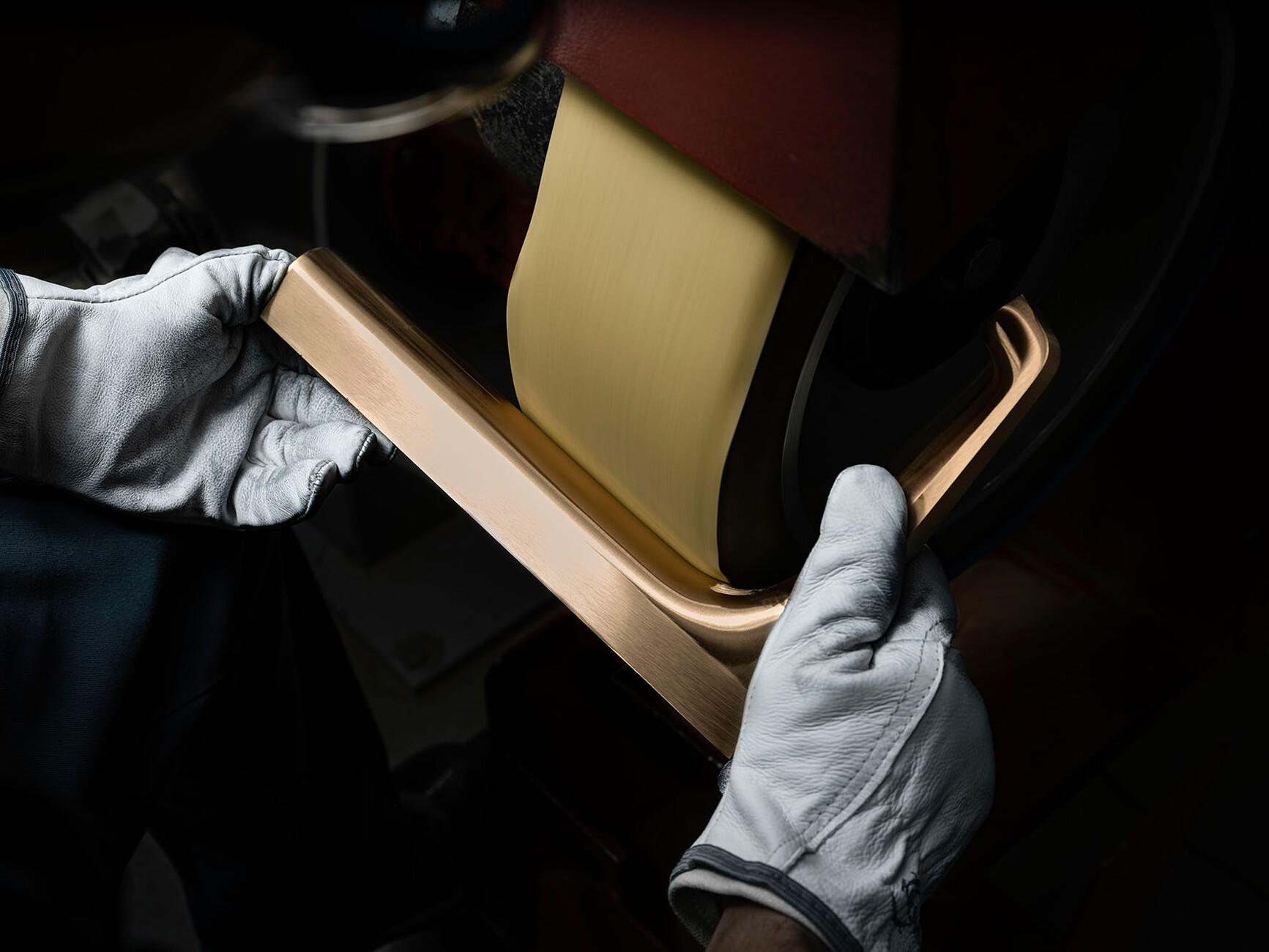

All AXOR products are produced in Europe, 90 percent of them at the AXOR Center for Excellence in the Black Forest. All production sites are also climate-neutral (Scope 1 & 2). Where is there still room for improvement?

Olivier Sogno: Water consumption, for example, is something we are constantly optimizing: With “AXOR Starck Organic”, we launched a faucet ten years ago that uses just 3.5 liters per minute. When it comes to showers, it is also crucial for us that the level of comfort remains the same even with a reduced water volume. That’s something we can achieve with innovative technologies – such as “PowderRain”, a water jet that covers the body and yet uses less water. With an eye on materials, too, we are finding potential for optimization, be it with textile shower hoses made of PET bottles or replacements for energy-intensive ceramic components, for example with solid surface material.