In a new light

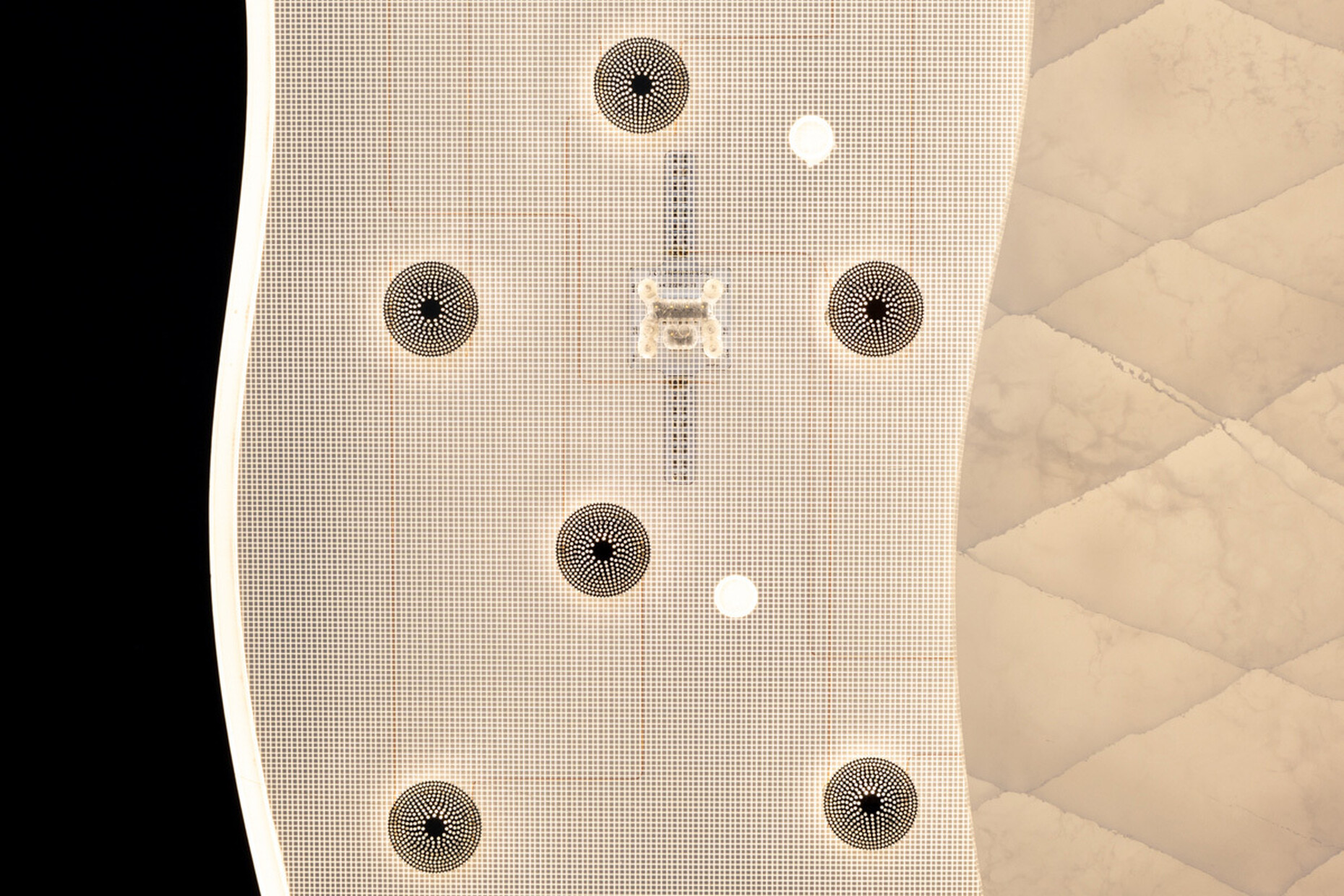

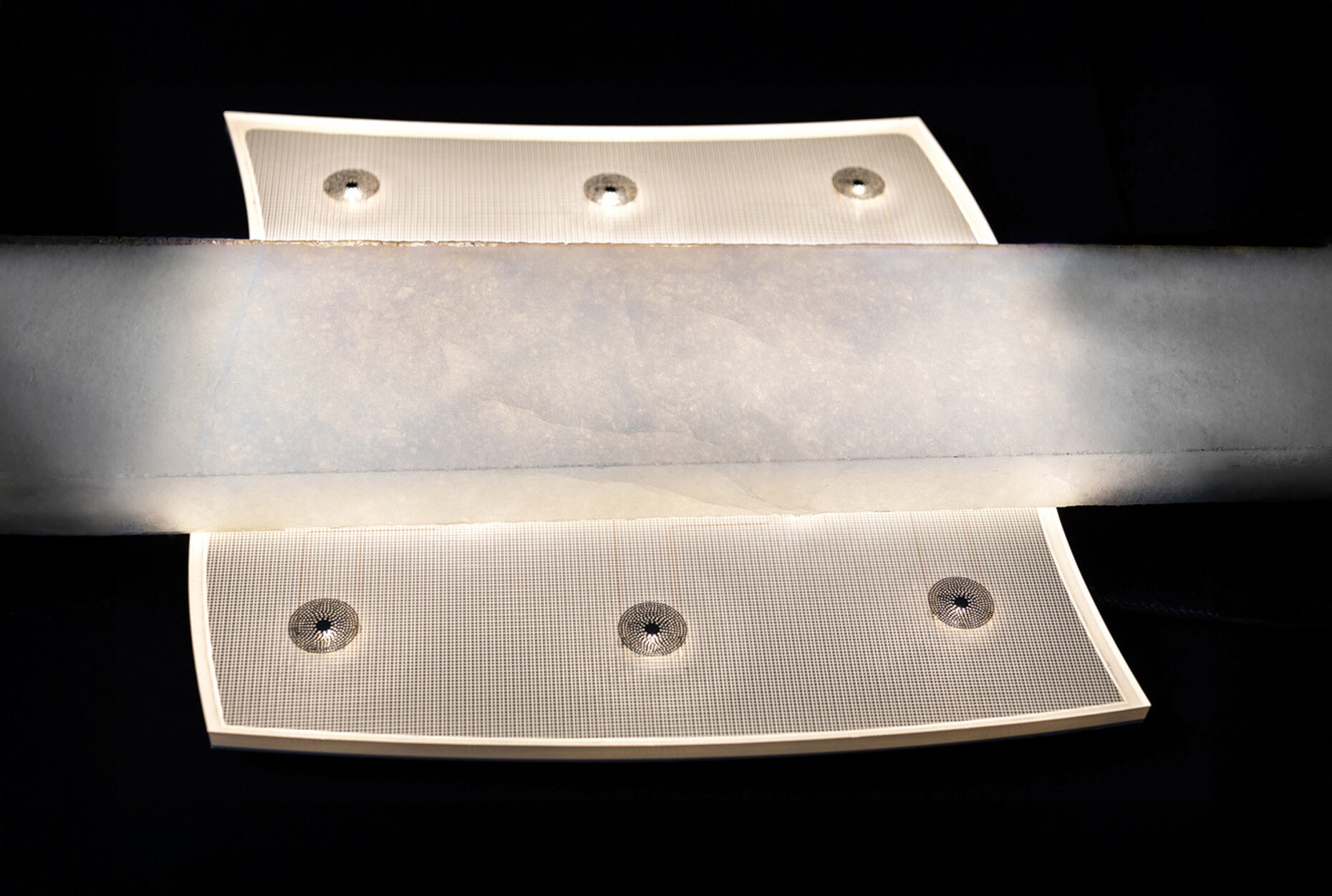

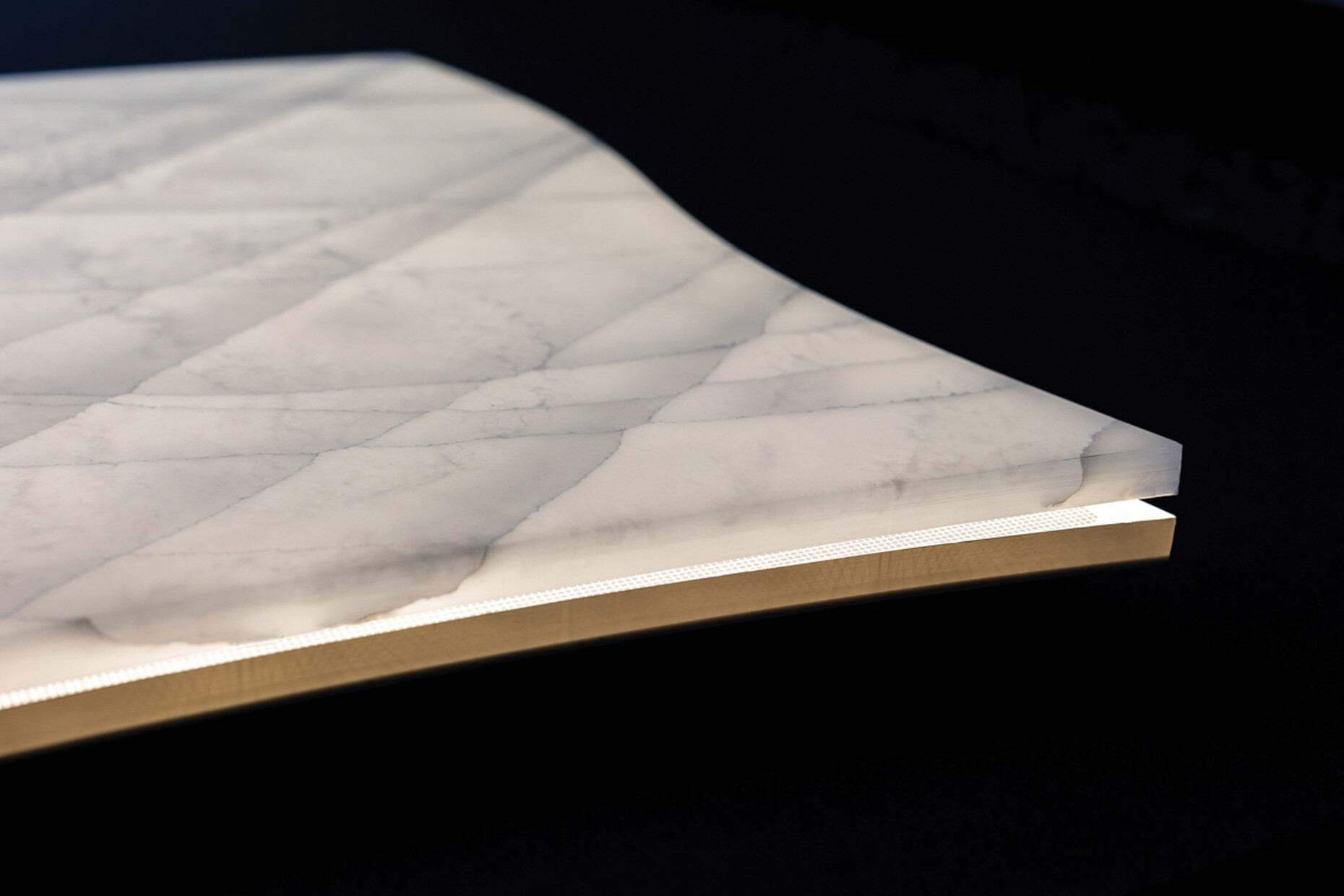

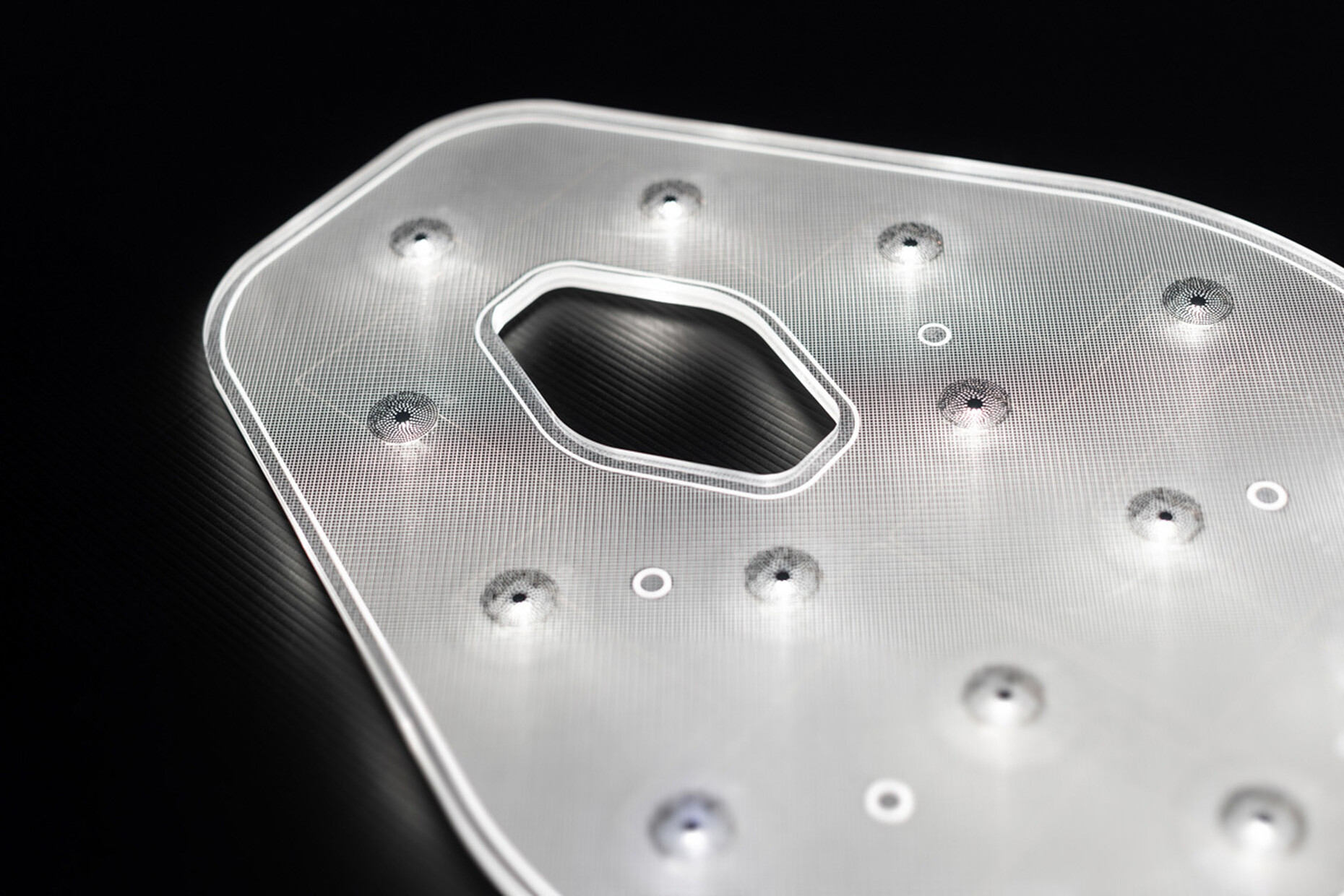

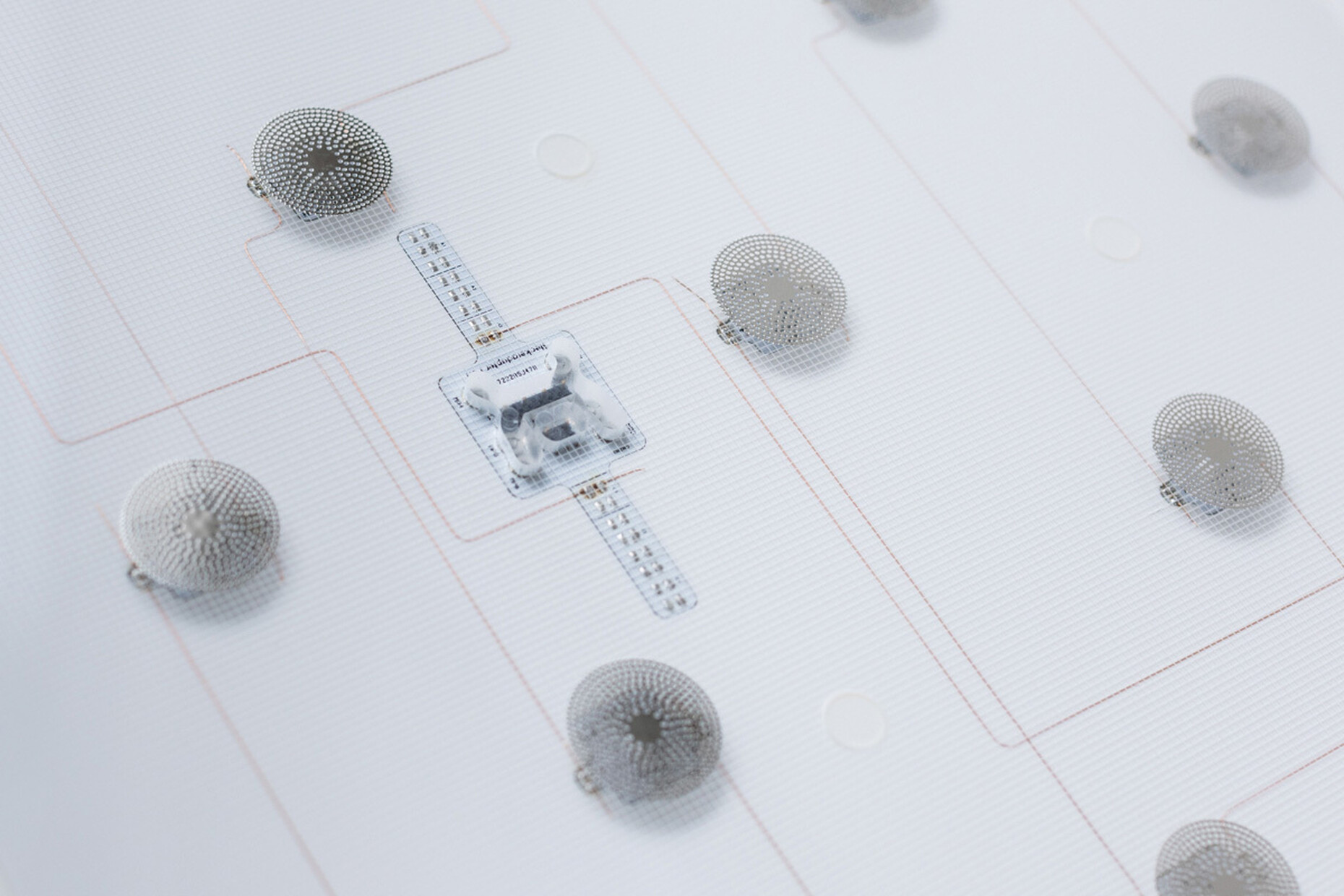

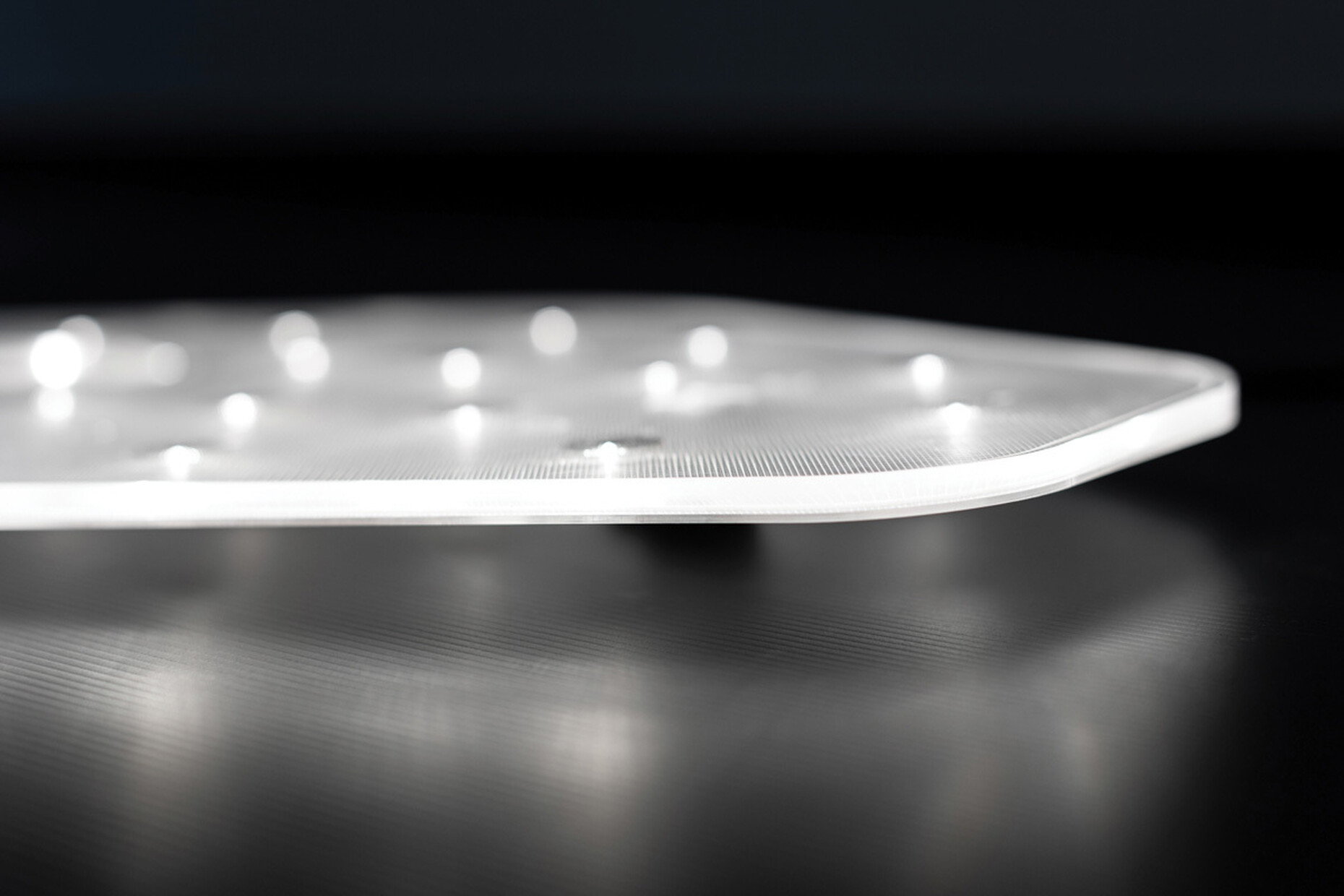

‘Printed light’ is no longer a foreign concept for the industry thanks to Ambright: founded in 2009, the Munich-based company offers a technology that opens up new possibilities for lighting design. The LEDs are freed from their placement on a circuit board and can be positioned on various surfaces and electronically connected to each other using an automated process. The result is high-quality customised products: In addition to pendant and wall lights, their repertoire also includes panel lights that enable the backlighting of translucent stone surfaces. The product line under the name ‘SparkSpace’ can be customised to any contours thanks to the flexible manufacturing process. This allows it to be integrated into existing architecture or customised furniture. Even the installation of loudspeakers, sprinklers or sockets need not remain a pipe dream thanks to the freely positionable openings in the panel light. In addition to the contour, the light colour, intensity and type of control can also be adapted to individual requirements.

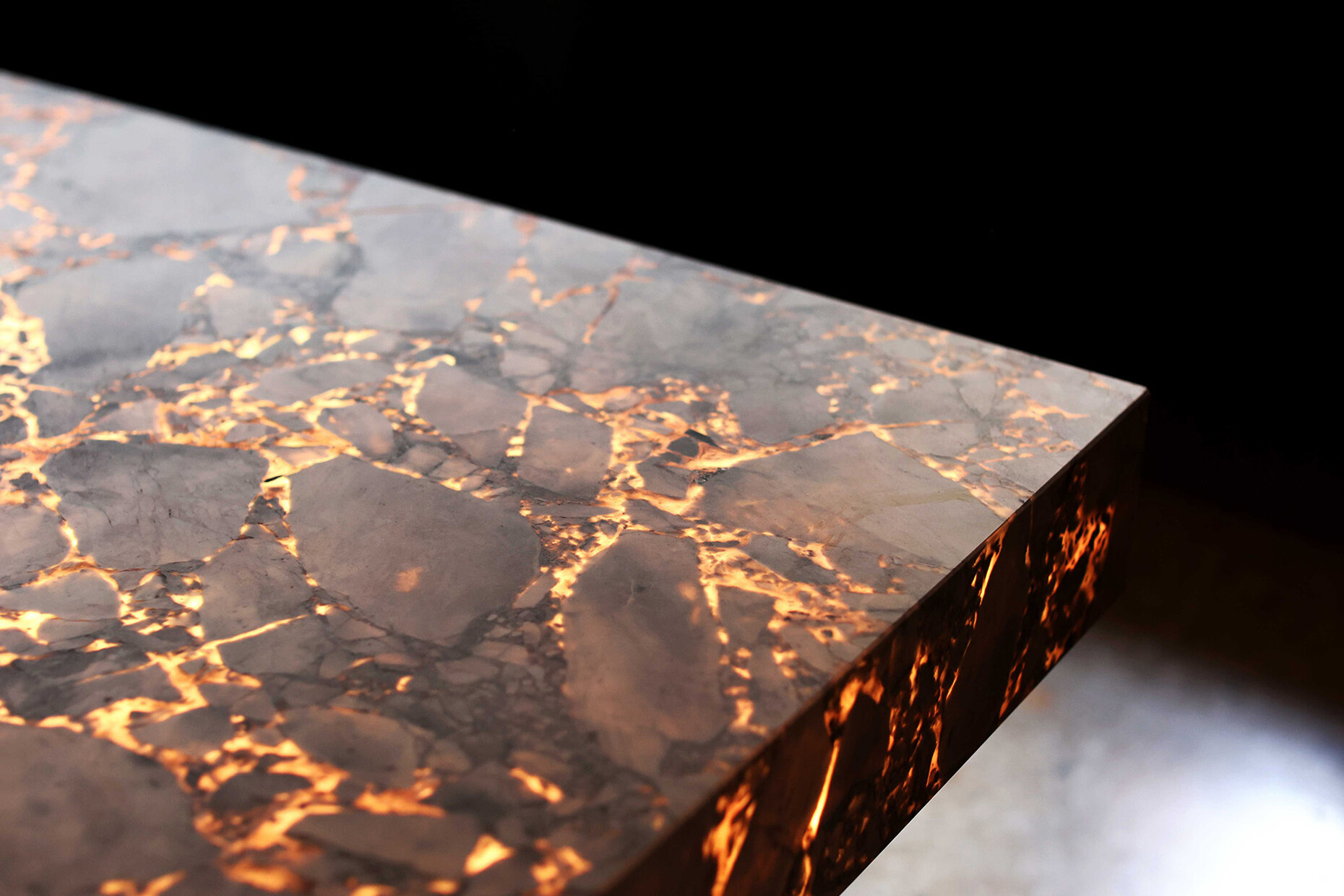

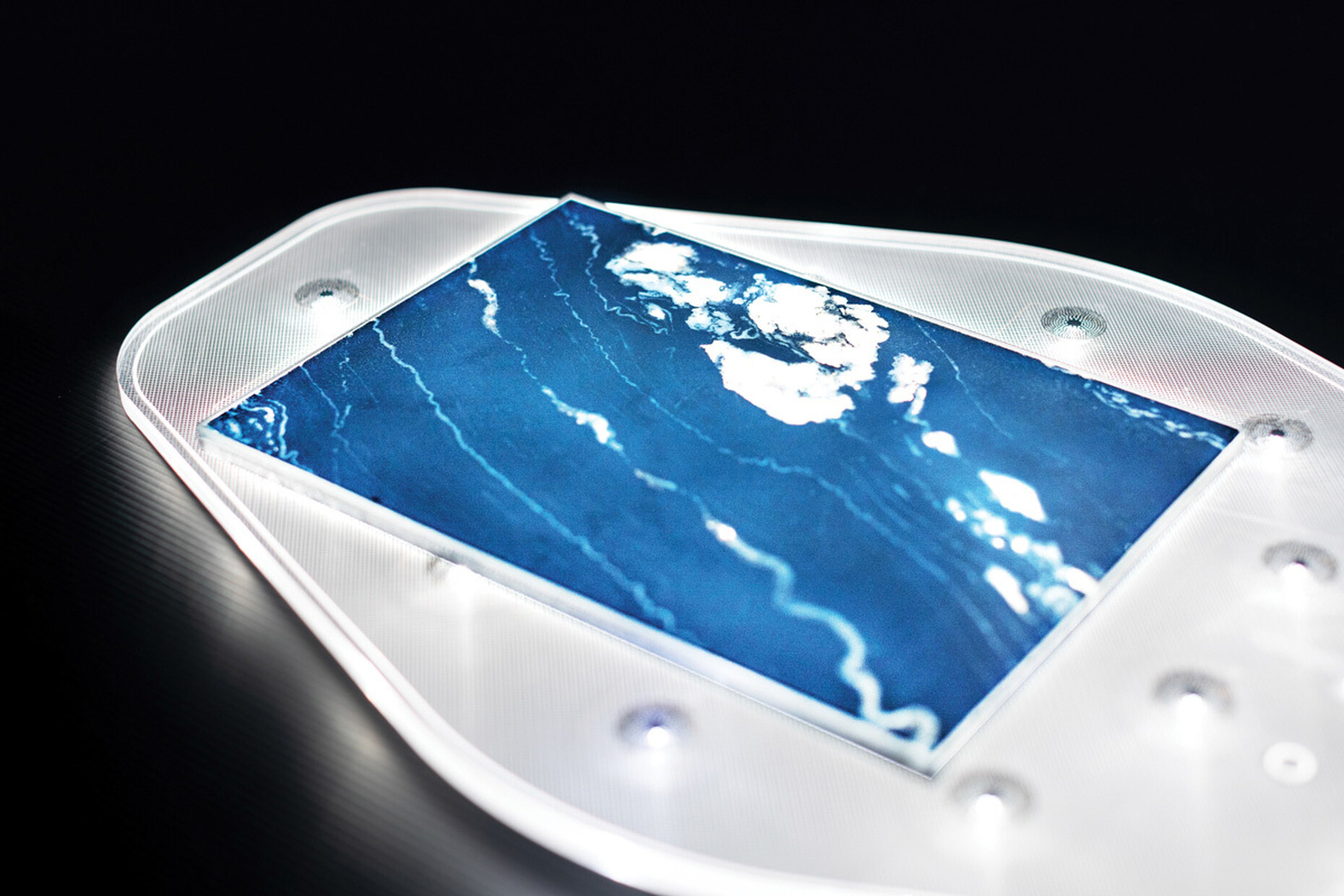

The fascinating lighting scenarios that can be realised with Ambright's panel lighting are demonstrated by their diverse range of fittings for luxurious yachts: Spacious counters, skilfully crafted from natural stone, are given an atmospheric backlighting for the home at sea with the light printing technology. Benjamin Kreis, master stonemason and stone sculptor at Jogerst Steintechnologie GmbH from Oberkirch, gives us an insight into the successful combination of craftsmanship and technology.

Anna Moldenhauer: What new design possibilities are offered by Ambright's panel lighting solutions?

Benjamin Kreis: There are stones that are already very well translucent in the usual slab thicknesses of two centimetres; these are often categorised as translucent stones. However, how well they can actually be illuminated depends on the type and thickness of the stone. In co-operation with our subsidiary Lixos, we produce a composite material that allows for significantly thinner stone thicknesses, thus significantly increasing the range of stones that can be used. The greatest difficulty here is getting enough light intensity behind the stone and achieving the most homogeneous illumination possible. This is usually achieved with very powerful light sources at a correspondingly large distance between the light source and the back of the stone. Ambright is the first manufacturer I know of who has managed to build a customisable light field that provides both high luminous intensity and very even diffusion. Mitred edges can now be created with very little shadowing. In the area of design, stone moulds can appear solid and illuminated. Thanks to the low overall thickness, illuminated fronts can now be added to the illuminated kitchen worktop.

The illumination is homogeneous, the light is scattered over the entire surface. Which stone is particularly suitable for the interplay of surface and light?

Benjamin Kreis: Generally speaking, stones with a high quartz content are suitable, but limestone can also be illuminated well. Provided the stone thickness is right. We have achieved very strong effects with Botanic Green, Azul Macaubas, Nero Marinace and Verde Alpi. One of my favourite stones is enjoying steadily growing popularity and, of course, also with those of our market companions. Taj Mahal, a quartzite from Brazil, warm beige-grey-brown basic colours, interspersed with high-contrast brown-gold veins, with a wild or rather calm grain, depending on the stone block. We also used this stone for our workpiece in collaboration with Ambright. A counter for reception at trade fairs and as an eye-catcher. Previously on show at Stone+Tec 2024 in Nuremberg and at our in-house exhibitions. On 12 and 13 April 2025, we will once again be inviting visitors to our factory in Oberkirch, where the illuminated counter will of course also be on display.

The translucent stone is placed on the light sources – how can they be maintained?

Benjamin Kreis: This depends on the intended use and must be planned for the respective circumstances. Using wall panelling as an example, a frame can conceal the actual load-bearing screw connection, allowing the stone wall to be detached from the panel. In the area of a kitchen worktop, the lighting elements can be achieved by removing one or more carcasses. In my experience, the power supply units need to be accessible. In the example of the kitchen, these are usually located under the cupboards on the floor or are screwed into a cupboard. With wall panelling, the power supply units are often installed in the neighbouring room and the cable feed is routed through a hole to the LED panel.

To summarise: Ambright's panel lighting can be used to create an interior design that meets the highest standards and illuminates new perspectives with a variety of designs, whether in high-quality living areas or exclusive yacht construction. Translucent materials such as natural stone, glass or acrylic can be homogeneously illuminated from the inside with little installation space using Ambright technology. Each lighting solution is therefore unique – developed and produced in Munich.