Light you can shape at will

Ambright’s core competence is light that can be customized to specific needs. To this end, the Munich-based luminaire maker offers flexible solutions that designers can use to realize their ideas freely in terms of both shape and materials. This is possible by means of so-called printed-light technology, a patented process that Ambright itself developed. In this way, LEDs can be positioned at will on various different surfaces and then electronically connected to one another. Ambright’s LightSketch platform provides additional support for designers when fleshing out their ideas. The specific lighting solutions can therefore be custom-planned and then manufactured in Munich, even if only one iteration of the product is required. The luminaires can be configured spatially just as flexibly as they can be designed, and range from ceiling and wall-mounted pieces to highly atmospheric back lighting.

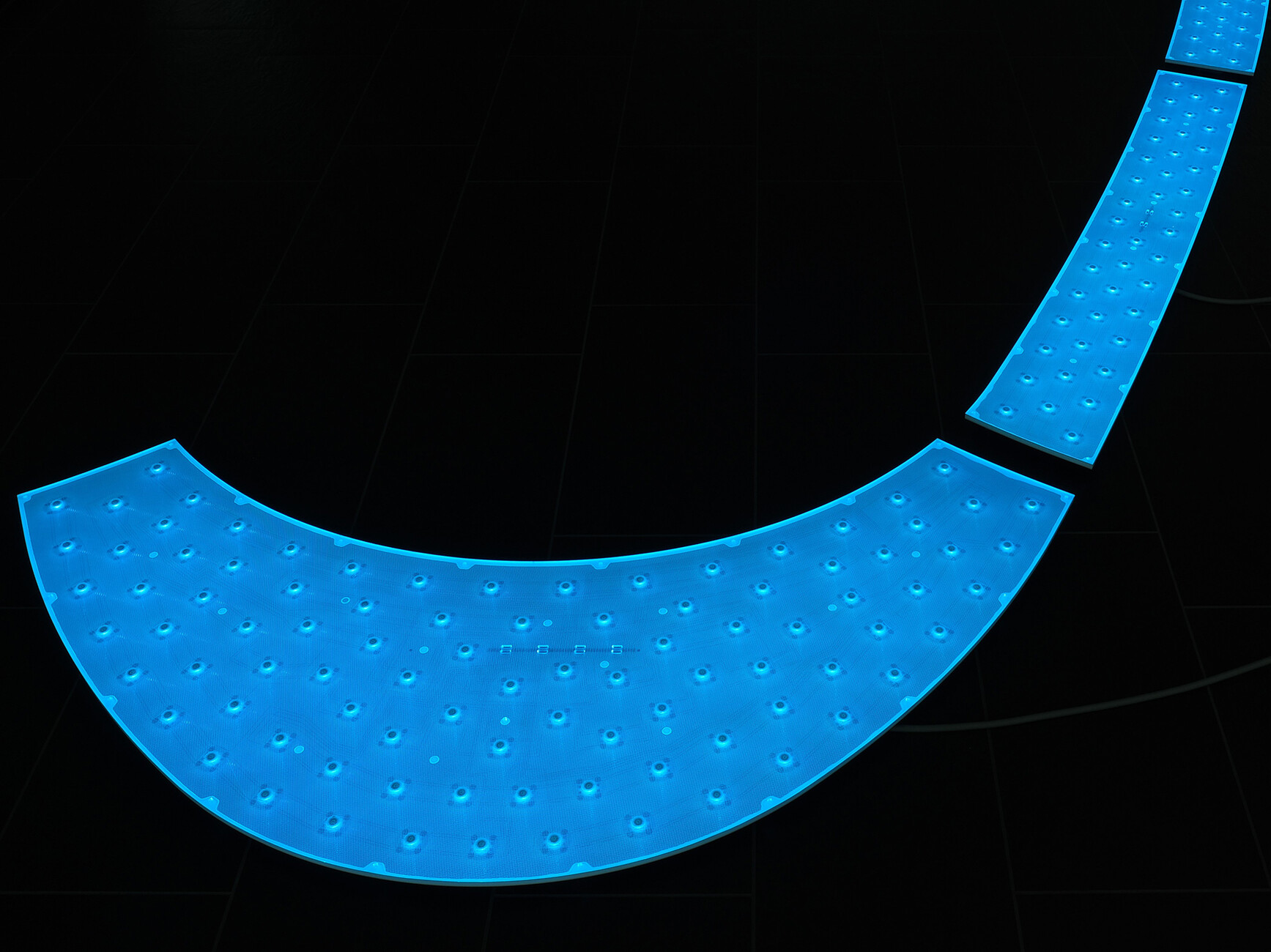

“Flächenlicht” is a prime example and can be used to clad not just walls, but also for ceilings, counter tops, pillars, or wainscotting. “Flächenlicht can be brought to bear in the form of our ‘Dot Injection Panel’ whenever you need to back-light large surfaces. If furniture, walls, wall cladding or other objects need to be highlighted by means of light hidden in the material then we custom-size the Flächenlicht accordingly. As a rule, the client wants to present selected high-grade materials and special surfaces by back-lighting them to great effect. For example, recently we deployed Flächenlicht for a panel made of Italian rock crystal in a luxurious kitchen. It looks extremely classy and imbues the room with a very special atmosphere,” says Carlo Fleischmann, Head of Project and Product Management at Ambright, describing the technical options and design scope.

What this actually involves is as follows: Using the Dot Injection Panel, light is injected into a light-conducting material at specific points and then spreads across the surface to be illuminated. Moreover, these panels are very thin and allow for special sizes, freeforms or cut-out shapes. In this way, they can even be integrated into units such as loudspeakers. To this end, “Flächenlicht” gets installed between the surface and the frame. Thanks to the printed-light technology, the LEDs can be flexibly inserted into the underlying light-conducting material. The result: total internal reflection and light coupled out evenly across the illuminated surface. Finally, a surface material is placed in front of the panel that is then homogeneously illuminated. In this way, panels made of natural stone or other translucent materials can be back-lit. Examples would be counter-tops clad in onyx or marbled walls as eye-catchers in high-profile areas, such as lobbies. In this way, Ambright’s “Flächenlicht” can be shaped at will, enabling architects, interior architects and designers to plan extraordinary lighting solutions and impressively stage rooms. It is therefore no surprise that it is featured in all manner of interior design projects right through to the staged lighting in luxury yachts.

This year Ambright is official lighting partner of Architect@Work 2023 Germany. A specialist committee consisting of architects and designers selected the Munich-based luminaire makers to exclusively present its products in the context of the trade fair.